Programming and Operating Manual (Milling)

142

6FC5398-4DP10-0BA1, 01/2014

Note

Depending on the settings in machine data MD30200 $MA_NUM_ENCS, the cycle selects whether tapping is to be

performed with or without encoder.

The direction of rotation for the spindle must be programmed with M3 or M4.

In thread blocks with G63, the values of the feedrate override switch and spindle speed override switch are frozen to 100%.

A longer compensating chuck is usually required for tapping without encoder.

AXN (tool axis)

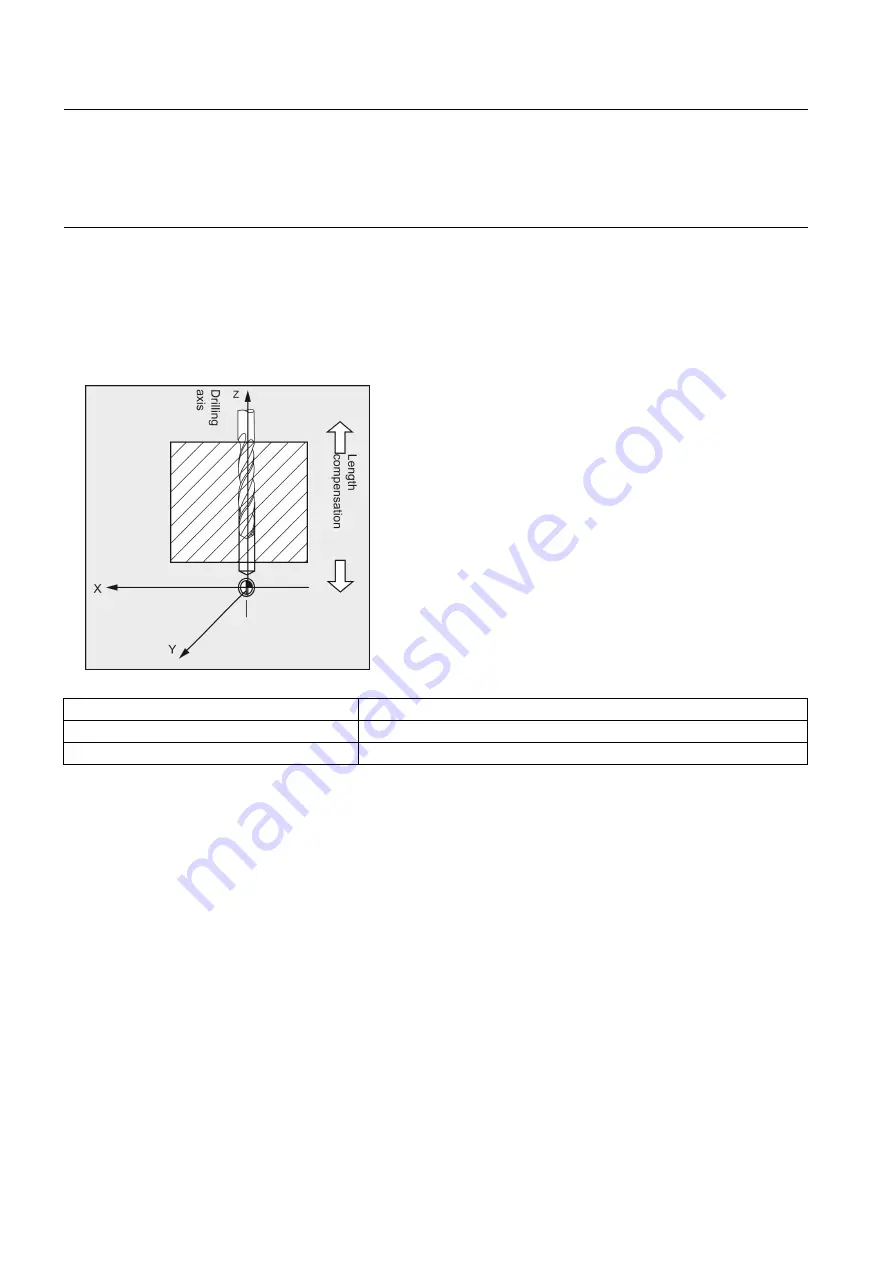

The following figure presents the options for the drilling axes to be selected.

With G17:

●

AXN=1; Corresponds to X

●

AXN=2; Corresponds to Y

●

AXN=3; Corresponds to Z

Using AXN (number of the drilling axis) to program the drilling axis enables the drilling axis to be directly programmed.

AXN=1

1st axis of the current plane

AXN=2

2nd axis of the current plane

AXN=3

3rd axis of the current plane

For example, to machine a hole in the G17 plane with Z axis, you program:

G17

AXN=3

Programming example: Tapping without encoder

In this program, a thread is tapped without encoder at position X35 Y35 in the XY plane; the tapping axis is the Z axis. The

parameters SDR and SDAC for the direction of rotation must be assigned; parameter ENC is assigned the value 1, the value

for the depth is the absolute value. Lead parameter PIT can be omitted. A compensating chuck is used in machining.