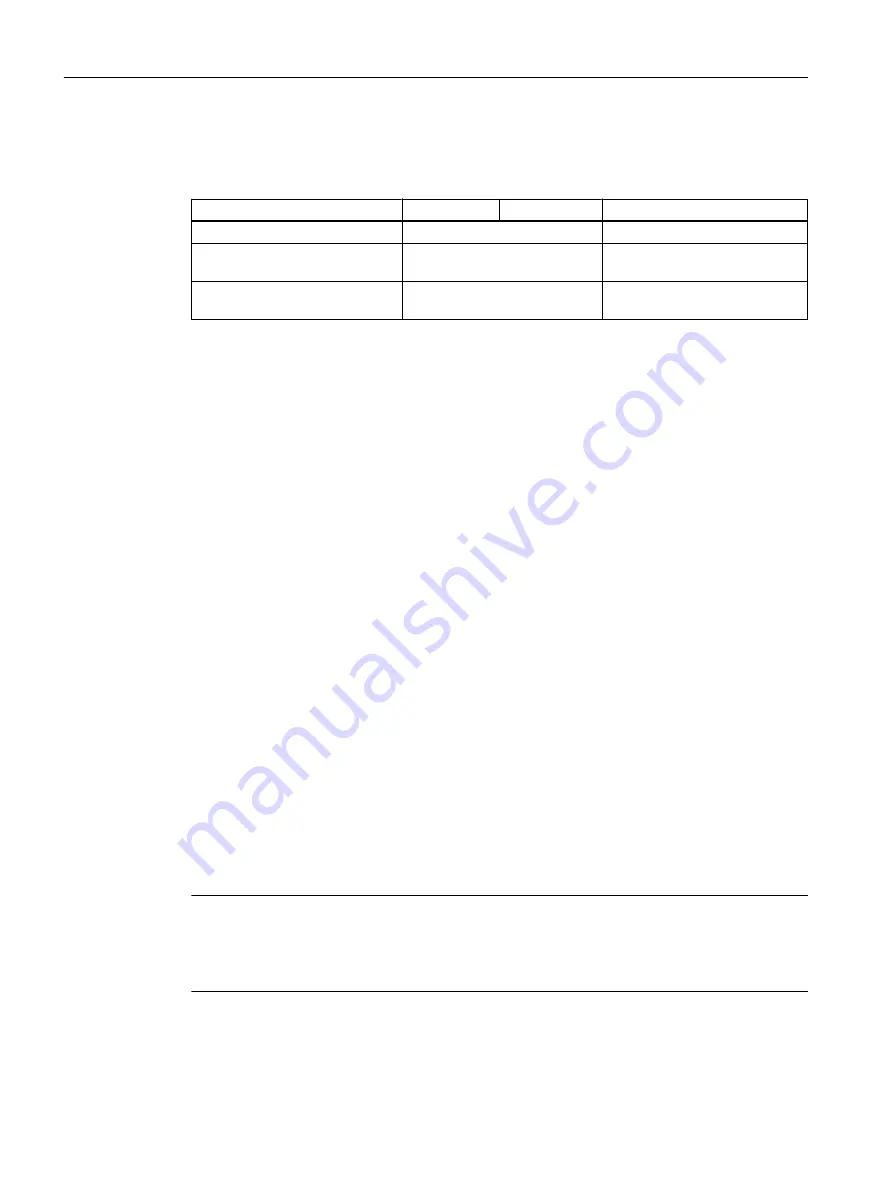

Properties of the Controller, Supervisor and drive units

Table A-2

Properties of the Controller, Supervisor and drive units

Properties

Controller

Supervisor

Drive unit

As bus node

Active

Passive

Send messages

Permitted without external re‐

quest

Only possible on request by the

Controller

Receive messages

Possible without any restrictions Only receive and acknowledge

permitted

Communication types

4 communication types are defined in the PROFIdrive profile:

● Cyclic data exchange via a cyclic data channel

Motion control systems require cyclically updated data in operation for open-loop and

closed-loop control tasks. This data must be sent to the drive units in the form of setpoints

or transmitted from the drive units in the form of actual values, via the communications

system. Transmission of this data is usually time-critical.

● Acyclic data exchange via an acyclic data channel

An acyclic parameter channel for exchanging parameters between the control/supervisor

and drive units is additionally available. Access to this data is not time-critical.

● Alarm channel

Alarms are output on an event-driven basis, and show the occurrence and expiry of error

states.

● Isochronous mode

– Cyclic data exchange in a fixed time grid

– The controller and device are synchronized

Interface IF1 and IF2

The CU320-2 Control Unit can communicate via two different interfaces (IF1 and IF2).

Both interfaces can be allocated the following physical interfaces:

● (1) On-board X126 PROFIBUS/X150 PROFINET

● (2) Communication Board X1400

Note

Ethernet interface X127 is intended for commissioning and diagnostics.

Do not use this interface for other purposes (e.g. field bus communication) and ensure that

X127 (e.g. for service) is always accessible.

Communication

A.1 Communication

Industrial Security

84

Configuration Manual, 08/2017, A5E36912609A