Rockwell Automation Publication 2080-UM002N-EN-E - November 2022

331

Appendix E PID Function Blocks

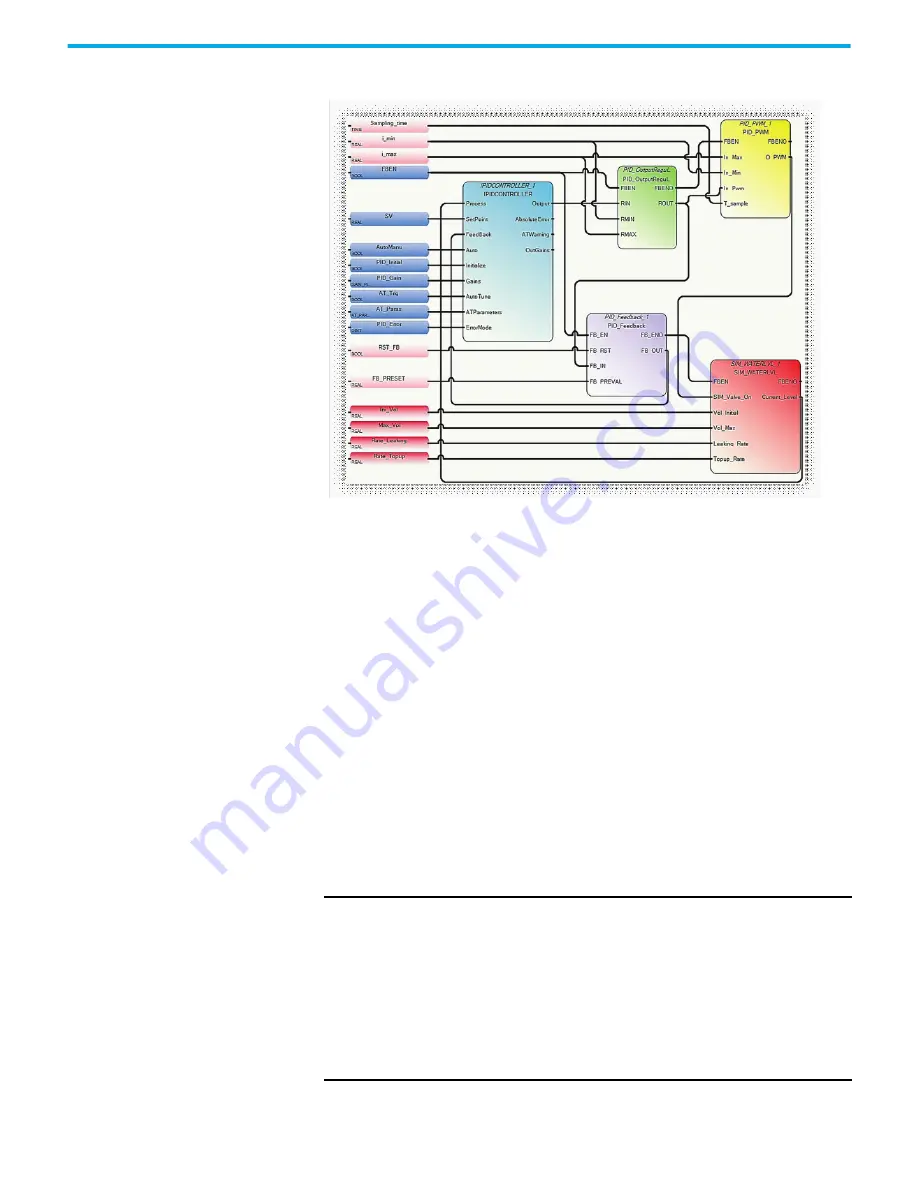

PID Code Sample

The illustration PID Code Sample shows sample code for controlling the PID application

example shown before. Developed using Function Block Diagrams, it consists of a pre-defined

function block, IPIDCONTROLLER, and four use-defined function blocks. These four are:

• PID_OutputRegulator

This user-defined function block regulates the output of IPIDCONTROLLER within a safe

range to ensure that there is no damage to the hardware used in the process.

IF RMIN

≤

RIN

≤

RMAX, then ROUT = RIN,

IF RIN < RMIN, then ROUT = RMIN,

IF RIN > RMAX, then ROUT = RMAX.

• PID_Feedback

This user defined function block acts as a multiplexer.

IF "FB_RST" is false, FB_OUT=FB_IN;

If "FB_RST" is true, then FB_OUT=FB_PREVAL.

• PID_PWM

This user defined function block provides a PWM function, converting a real value to a

time-related ON/OFF output.

• SIM_WATERLVL

This user defined function block simulates the process depicted in the application

example shown before.

IMPORTANT

User Program Scan Time is Important

The autotuning method needs to cause the output of the control loop to

oscillate. In order to identify the oscillation period, the IPID must be

called frequently enough to be able to sample the oscillation adequately.

The scan time of the user program must be less than half the oscillation

period. In essence the Shannon, or Nyquist-Shannon, or the sampling

theorem must be adhered to.

In addition, it is important that the function block is executed at a

relatively constant time interval. One can typically achieve this using STI

interrupt.