2.2.6. Development

Overview

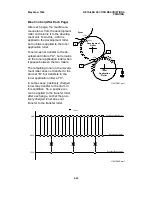

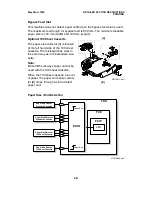

There are two development rollers in the development unit: the Toner Applica-

tion Roller and the Development Roller.

The toner supply bar [A] stirs and carries toner to the toner application roller

[B]. Toner is attracted to the toner application roller because it has a magnetic

layer. As the toner application roller turns past the toner metering blade [C],

only a thin coating of negatively charged toner particles stays adhered. (Refer

to section 4-4-2 of the Group 3 Facsimile manual.)

During printing, a bias voltage of -700 V is applied to the toner application

roller and another bias voltage of -400 V is applied to the development roller.

The toner is carried from the toner application roller to the development roller

[D] by the potential difference between these two rollers.

The exposed area on the drum [E] is at -100 V. The development roller ap-

plies toner to these areas of the latent image as they turn past the drum.

The development roller is made of a soft rubber so it does not damage the

surface of the drum. The development roller is provided as a separate spare

part because it always contacts the toner application roller, and so may be-

come dented.

The speed ratio between the drum, development roller, and the toner applica-

tion roller is about 1 : 1 : 3. The toner application roller rotates three times as

fast as the development roller, so it deposits a layer of toner three times as

thick on the development roller. This leads to a clearer image. Also, the toner

application roller rotates in the opposite direction to the development roller,

which helps to keep the toner level on the development roller.

[C]

[A]

[B]

[D]

[E]

H521D616.wmf

May 22nd, 1995

DETAILED SECTION DESCRIPTIONS

PRINTING

2-33