172

⿎

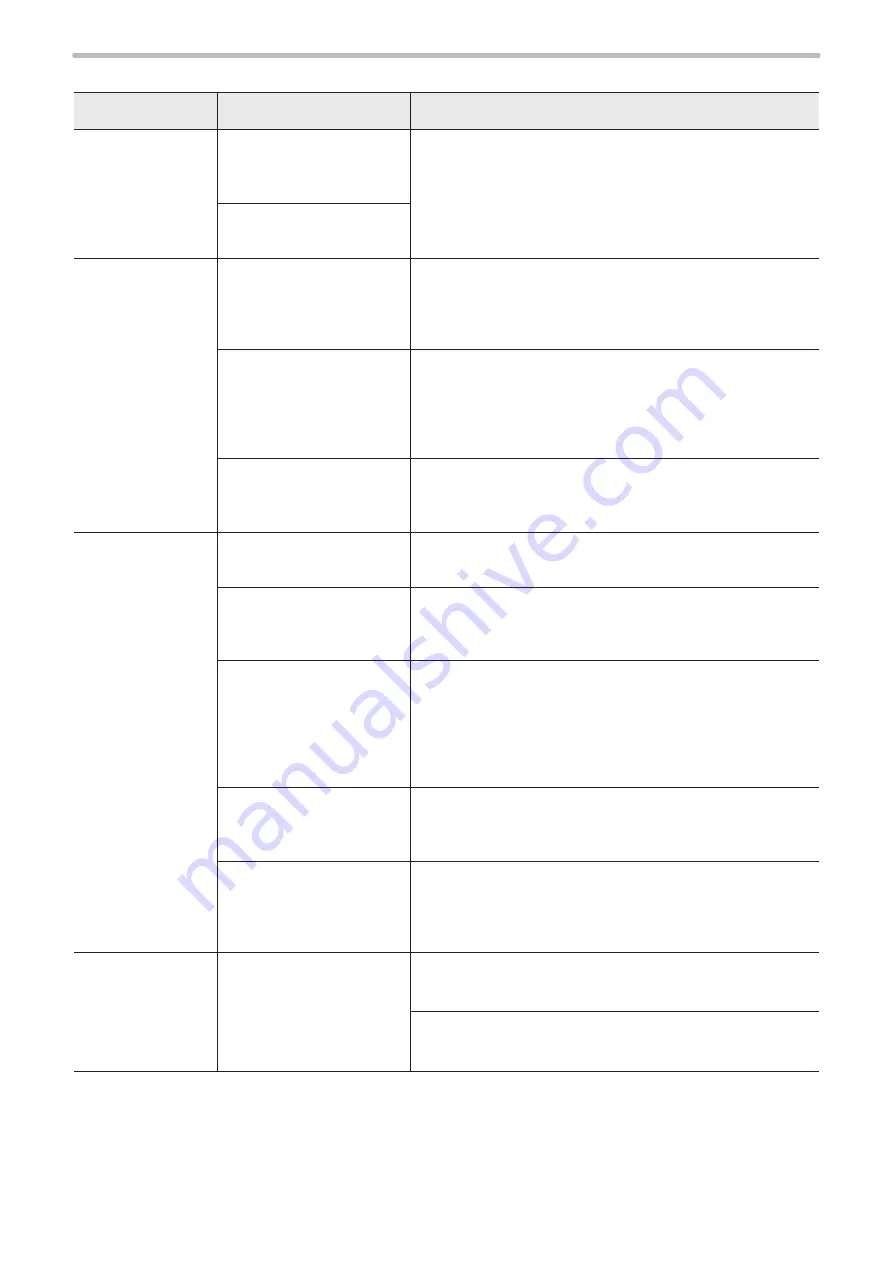

Link control with external devices

Troubles

Causes

Measures

Link control with

image checker and

code reader fails

The connections with the

image checker or code

reader are inadequate.

• Refer to Setup/Maintenance Guide for the wiring and

communication settings.

• If the Ethernet communication settings or RS-232C usage are

changed, restart the laser marker.

Communication settings are

inadequate.

Marking cannot

be done in an

appropriate position

when the function of

position correction is

used

The coordinates of the image

checker are not consistent

with the marking position of

the laser marker.

Set the calibration of the image checker and match the

coordinate origin of the image checker to the center point of the

marking field of the laser marker.

Settings of the image checker

are inadequate.

Confirm the following settings of PV230/PV200.

• Setting of Ethernet with the protocol General communication

• Calibration

• Settings of the positional correction

• Expression of the numeric calculation

The setting order of the

expression table of PV230/

PV200 is inadequate.

The results of the numerical calculation should output to the laser

marker in the order of X, Y, and theta.

The results of the

code or character

checking is NG.

Testing conditions of image

checker are inadequate.

Set appropriate testing conditions of the image checker

according to marked code type or character settings.

Unnecessary objects are

included in the captured

image.

Do not place the code symbols or characters other than the

image checking target in the imaging range.

When PV230 is used:

Settings of the total

judgement are inadequate.

• For code checking, confirm the settings of the code reader

checker of PV230.

• For character checking, confirm the settings of the OCR

checker of PV230.

• Cofirm the expression of the numeric calculation in the total

judgement.

When PV230 is used:

No settings in the character

dictionary of PV230.

To use the character recognition function, set the dictionary of

PV230 for each marking character beforehand.

Ghost image of fumes

(smoke) occurring during

marking is taken in the

shooting range.

• Install a dust collector to get rid of fumes (smoke).

• Check that the dust collector works well.

Marking disorder

Since the work feeding and

marking start/end timing are

inadequate when TIMING IN

signal is used, the vibration

affects marking.

Turn TIMING IN signal ON after work piece is fully stopped.

To feed works after marking, check that TIMING WAIT OUT is

turned ON and start feeding works.

ME-LPGS-SM-8

Summary of Contents for LP-GS Series

Page 17: ...1 Product Overview ME LPGS SM 8 ...

Page 32: ...2 Laser Marker Installation ME LPGS SM 8 ...

Page 48: ...3 Operation Method ME LPGS SM 8 ...

Page 68: ...4 External Control Using I O ME LPGS SM 8 ...

Page 107: ...5 External Control by Communication Commands ME LPGS SM 8 ...

Page 116: ...6 Link Control with External Devices ME LPGS SM 8 ...

Page 141: ...7 Maintenance ME LPGS SM 8 ...

Page 161: ...161 MEMO ME LPGS SM 8 ...

Page 162: ...Troubleshooting ME LPGS SM 8 ...

Page 186: ...Index ME LPGS SM 8 ...

Page 189: ......

Page 190: ... Panasonic Industrial Devices SUNX Co Ltd 2014 2019 April 2019 ...