144

7-2-2 Intake/exhaust vent

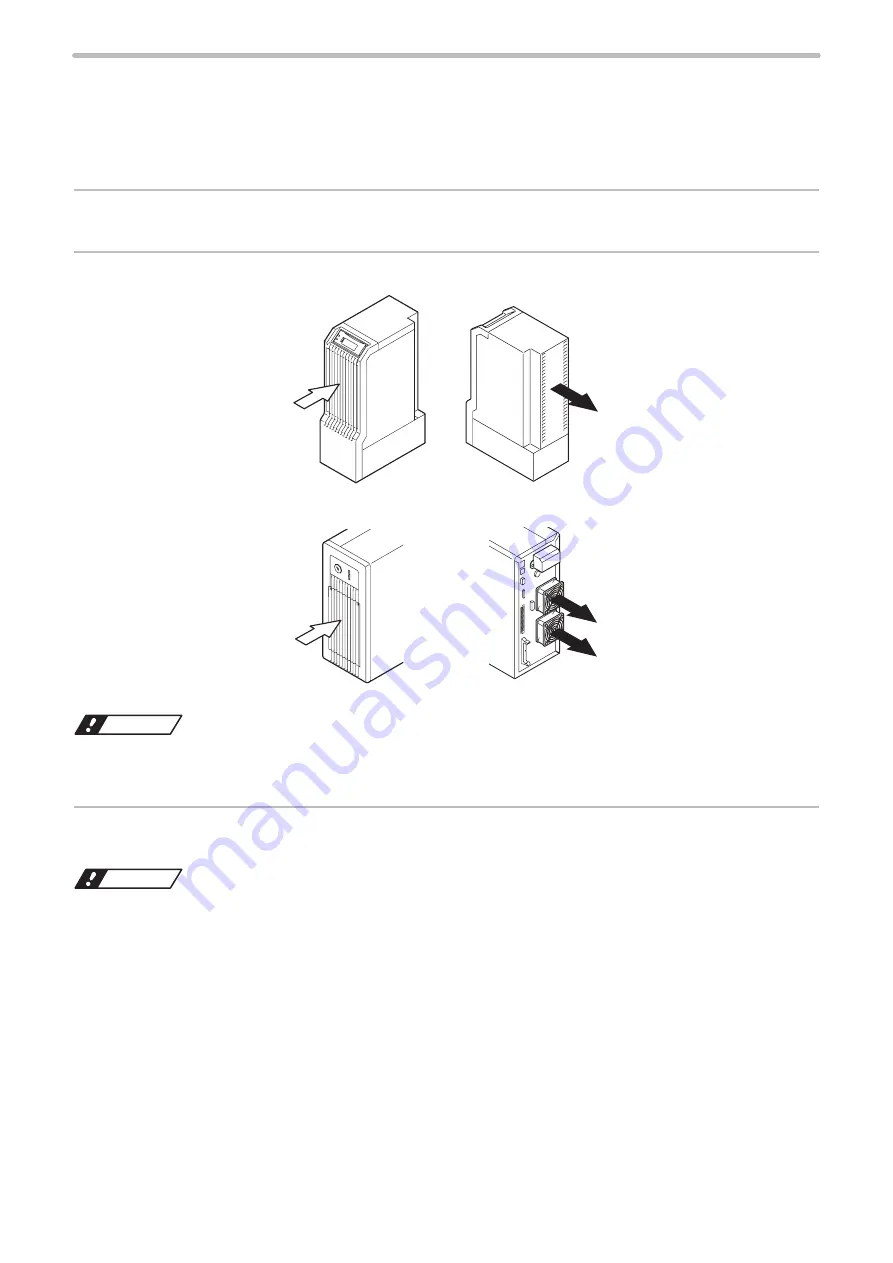

Air-cooling system is used in the laser marker, thus the cooling effect will drop if dust is adhered to the intake or exhaust

vent and it may result in the failure of the laser marker. Clean them regularly according to the usage environment.

Cleaning of the intake/exhaust vent (Daily maintenance)

1.

Turn OFF the key switch of the controller, and disconnect the AC power cable.

2.

Vacuum the intake/exhaust vent and remove the dust.

q

w

q

w

Head

Controller

q

Intake

w

Exhaust

ワㄐㄕㄊㄆ

• Do not blow air to the intake/exhaust vent. If the dust penetrates in the laser marker, it may results in failure.

3.

Wipe the vent with a dried cloth. If a contamination is severe, use a cloth wrung out with neutral

detergent to wipe it. Then, remove the detergent with a cloth wrung out of water.

ワㄐㄕㄊㄆ

• Keep water from entering the laser marker inside.

ME-LPGS-SM-8

Summary of Contents for LP-GS Series

Page 17: ...1 Product Overview ME LPGS SM 8 ...

Page 32: ...2 Laser Marker Installation ME LPGS SM 8 ...

Page 48: ...3 Operation Method ME LPGS SM 8 ...

Page 68: ...4 External Control Using I O ME LPGS SM 8 ...

Page 107: ...5 External Control by Communication Commands ME LPGS SM 8 ...

Page 116: ...6 Link Control with External Devices ME LPGS SM 8 ...

Page 141: ...7 Maintenance ME LPGS SM 8 ...

Page 161: ...161 MEMO ME LPGS SM 8 ...

Page 162: ...Troubleshooting ME LPGS SM 8 ...

Page 186: ...Index ME LPGS SM 8 ...

Page 189: ......

Page 190: ... Panasonic Industrial Devices SUNX Co Ltd 2014 2019 April 2019 ...