Service manual

XLP 504 / XLP 506

05/2018 | 09

125

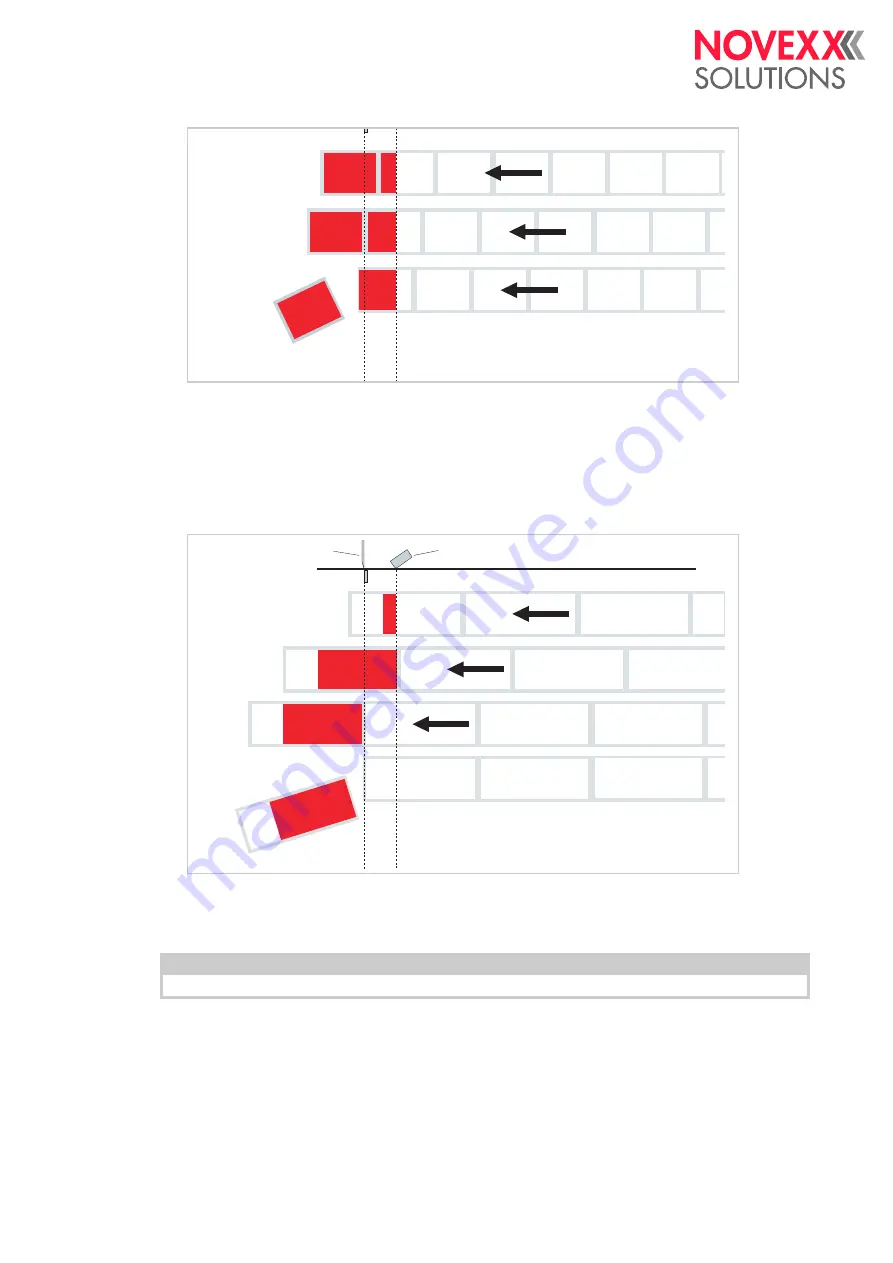

[142]Printing process in Batch mode (schematic).

•

Normal 1:1 mode

: In N1:1 mode, cutting takes place during printing. The zero-line of the printing

is shifted 18 mm in y-direction. This offset equals the distance cutter-print head. Caused by this

shifting, the first 18 mm of the label are not printable. These measurement corresponds to the

distance between print head and cutter. The output volume is at its maximum level.

(The offset of the zero-line is caused historically and serves the compatibility of older printer

models).

[143]Printing process in Normal 1:1 mode (schematic).

Cut speed

Only with mounted and activated cutter (

Options > Selection > Periph. device

= „Cutter“).

The cut speed is to be adjusted to the material thickness and strength.

• 2: Extremely slow; for thick and strong material

• 5: Extremely fast; for thin material

Setting range

Default setting

Step width

Easy Plug

[2...5]

3

1

#PC1015

Novexx

Novexx

Novexx

Novexx

Novexx

Novexx

1. Printing

2. Stop pr

cut

3. Continue

printing

Novexx

Novexx

Novexx

Novexx

Printhead

Cutter

1. Printing

2. Printing

End

3. Feeding

4. Cutting

Summary of Contents for XLP 504

Page 1: ...Edition 9 5 2018 Translation of original version SERVICE MANUAL XLP 504 XLP 506 Label printer ...

Page 2: ......

Page 238: ...Service manual XLP 504 XLP 506 05 2018 06 238 Appendix WIRING DIAGRAMS See next pages ...

Page 248: ...Novexx Solutions GmbH Ohmstraße 3 85386 Eching Germany 49 8165 925 0 www novexx com ...