6 OPTIONS AND PERIPHERAL EQUIPMENT

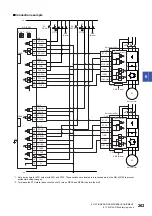

6.17 MR-J3-D05 safety logic unit

259

6

Precautions

The following basic safety instructions must be read carefully and fully to prevent injury to persons or damage to property.

Only qualified personnel are authorized to install, startup, repair, or adjust the machines in which these components are

installed.

They must be familiar with all applicable local regulations and laws in which machines with these components are installed,

particularly the standards mentioned in this user's manual and the requirements described in ISO/EN ISO 13849-1, IEC

61508, IEC/EN 61800-5-2, and IEC/EN 60204-1.

The staff responsible for this work must be given express permission from the company to perform startup, programming,

configuration, and maintenance of the machine in accordance with the safety standards.

As described in IEC/EN 61800-5-2, the STO function (Safe Torque Off) only prevents the supply of energy from the MR-J5

series servo amplifier to the servo motor. Therefore, in situations where another power source may independently operate the

servo motor, additional safety measures, such as brakes and counterweights, must be implemented.

Residual risks

Machine manufacturers are responsible for all risk evaluations and all associated residual risks. Below are residual risks

associated with the STO/EMG functions. Mitsubishi Electric is not liable for any accidents such as damage and injuries

caused by these risks.

• The SS1 function only guarantees the delay time before STO/EMG becomes enabled. The company, group, or individuals

in charge of installation and delegation of the safety systems are fully responsible for correctly setting this delay time. In

addition, certification regarding safety standards over the whole system is required.

• The servo motor stops with a dynamic brake or by coasting in any of the following cases: when the SS1 delay time is

shorter than the servo motor deceleration time, when the forced stop function has a problem, or when STO/EMG is enabled

during servo motor rotation.

• For proper installation, wiring, and adjustment, thoroughly read the installation guide of each individual safety related

component.

• For all devices related to safety, such as relays and sensors, use devices that satisfy the safety standards. A Certification

Body has confirmed that the Mitsubishi Electric safety-related components mentioned in this manual satisfy ISO/EN ISO

13849-1 Category 3, PL d and IEC 61508 SIL 2.

• Safety is not assured until the safety-related components of the system are completely installed and adjusted.

• When replacing an MR-J5 series servo amplifier or the MR-J3-D05, confirm that the new servo amplifier or the new unit is

the same as the one being replaced. Once installed, be sure to verify the performance of the functions before

commissioning the system.

• Perform all risk assessments and obtain safety level certifications on the machine or the whole system. As the final safety

certification of the system, we recommend using a Certification Body.

• To prevent malfunctions from accumulating, perform the appropriate malfunction checks at the regular intervals defined in

the safety standards. Regardless of the system safety level, malfunction checks should be performed at least once per

year.

• If the upper and lower power modules in the servo amplifier are shorted and damaged simultaneously, the servo motor may

make a half revolution at a maximum.

WARNING

• An inappropriately installed safety device or system may lead to an operation status where safety cannot be assured, and a serious or fatal accident may

occur.

Summary of Contents for MELSERVO-J5 MR-J5-G Series

Page 2: ......

Page 473: ...12 USING A FULLY CLOSED LOOP SYSTEM 12 7 Absolute position detection system 471 12 MEMO ...

Page 477: ......