MI 3290 Earth Analyser

Tests and Measurements

101

11.7 Earth Potential [Us]

An earthing electrode / grid deployed into ground have a certain resistance, depending on its

size, surface (oxides on the metal surface) and the soil resistivity around the electrode. The

earthing resistance is not concentrated in one point but is distributed around the electrode.

Correct earthing of exposed conductive parts assures that the voltage on them stays below

dangerous level in case of a fault.

If a fault happens a fault current will flow through the earthing electrode. A typical voltage

distribution occurs around the electrode (the “voltage funnel”). The largest part of the voltage

drop is concentrated around the earth electrode.

contact voltages occur as a result of fault currents flowing through the earthing electrode /

grid in the ground.

Fault currents close to power distribution objects (substations, distribution towers, plants) can

be very high, up to 200 kA. This can result in dangerous step and contact voltages. If there

are underground metal connections (intended or unknown) the voltage funnel can get

atypical forms and high voltages can occur far from the point of failure. Therefore, the voltage

distribution in case of a fault around these objects must be carefully analysed.

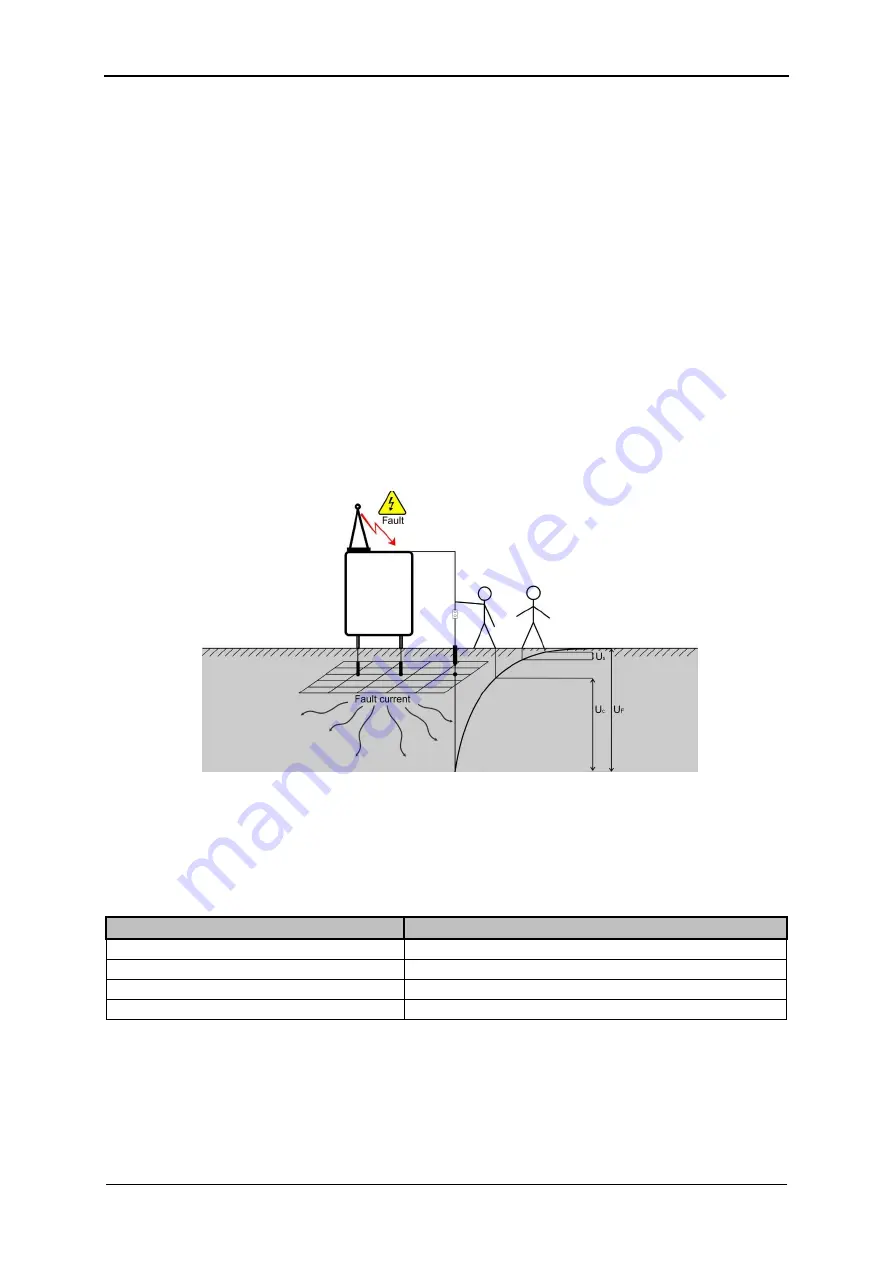

In the example below step and touch voltage are illustrated:

Figure 11.65: Dangerous voltages on a faulty earthing system

where:

U

S

..................................... Step Voltage in case of a fault current

U

C

..................................... Contact or Touch Voltage in case of a fault current

U

F

..................................... Fault voltage

Standard IEC 61140 defines following maximum allowed time / contact voltage relations:

Maximum time of exposure

Voltage

>5 s to ∞

UC

50 VAC or

120 VDC

0,4 s

UC

115 VAC or

180 VDC

< 0,2 s

UC

200 VAC

< 0,04 s

UC

250 VAC

Table 11.66: Maximum time durations vs fault voltage

For a longer exposure, the touch voltages must stay below 50 V.