Maintenance

45

Subject to technical changes.

200114

BA-42820-02-V03

Water sampling station

EASYPRO

Operating instructions

11 Maintenance

DANGER!

Mortal danger from electric shock!

Only work on electrical systems while the device is disconnected from

the power supply.

ð

Switch the system voltage-free.

ð

Secure the system to prevent it from being switched on again.

ð

Measure the absence of voltage in the system with a measuring

instrument.

ð

Earth the system and then short-circuit it.

ð

Cover adjacent live parts.

WARNING!

Increased risk of accidents due to insufficient qualifica-

tion of personnel!

The system and its accessories may only be installed, operated and

maintained by personnel with sufficient qualifications. Insufficient

qualification will increase the risk of accidents.

ð

Ensure that all action is taken only by personnel with sufficient and

corresponding qualifications.

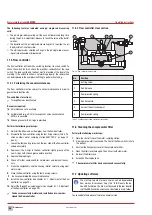

11.1 Maintenance intervals

The product require regular maintenance to prevent errors. This table

gives you an overview of the maintenance work.

Interval

Maintenance

daily

n

Visual inspection of all components

Weekly

n

Check measured values

n

Recalibrate sensor inputs if necessary

n

Visual inspection of the sample water filter

n

If necessary, cleaning of the sample water filter

Monthly

n

Touchscreen function test (

TOPAX

®

MC

)

n

Calibrating the measured values (

TOPAX

®

MC

)

n

Control of the flow controller

Annually

n

Checking the button cell

n

Cleaning the valves

n

Replacing the measuring cells

n

Replacing the sample water filter

n

Cleaning of water guiding components

n

Seal replacement

n

Maintenance of the flow controller

n

Replacing the O-rings of the flow controller

n

Replacing the diaphragm of the flow controller

Tab. 41: Maintenance intervals

11.2 Finishing maintenance

Perform the following work steps:

1.

Make a note of the date and scope of the maintenance performed.

2.

In the “Service” menu, navigate to the “Service entry” tab. Enter your

company name and notes about the maintenance. Activate the re-

minder function and enter a date for the next service. Confirm with

the “Save” button .

4

Your service action has been saved in the logfiles.

3.

To restart the system, proceed in accordance with the instructions in

section 8 „Commissioning of the water sampling station“ on page

28.

ü

Maintenance completed.

11.3 Keeping logfiles

If you make an entry in the logfiles, the device will issue a reminder when

a sensor needs to be replaced.

Perform the following work steps:

1.

Working in the main menu, navigate to System > Service > Service

entry and working under “Service entry” / “Sensor”, select the de-

sired sensor.

2.

Enter the serial number in the tab and the manufacturing company of

the sensor.

3.

Activate the reminder function and enter a date for the next sensor

change.

ü

Logfiles maintained.

11.4 Measuring cells

PLEASE NOTE

Note the service life of the measuring cells

The service life of the measuring cells is approx. 12 to 15 months,

whereby the storage time must be taken into account at 50 %. If the

service life is exceeded, this may distort measurement results.

ð

Note the printed date of manufacture and replace obsolete measur-

ing cells in good time.

The service life of the single-rod measuring cells depends on the operat-

ing conditions and the water properties (e.g. corrosiveness, grease etc.).

In normal conditions the service life will be 12 – 15 months, which in-

cludes 50 % storage time. The counter electrode of the disinfection meas-

uring cell can have a service life of up to several years, depending on the

corrosiveness and the abrasiveness of the water. It must only be replaced

when heavy signs of wear appear.