Commissioning of the water sampling station

32

BA-42820-02-V03

Water sampling station

EASYPRO

Operating instructions

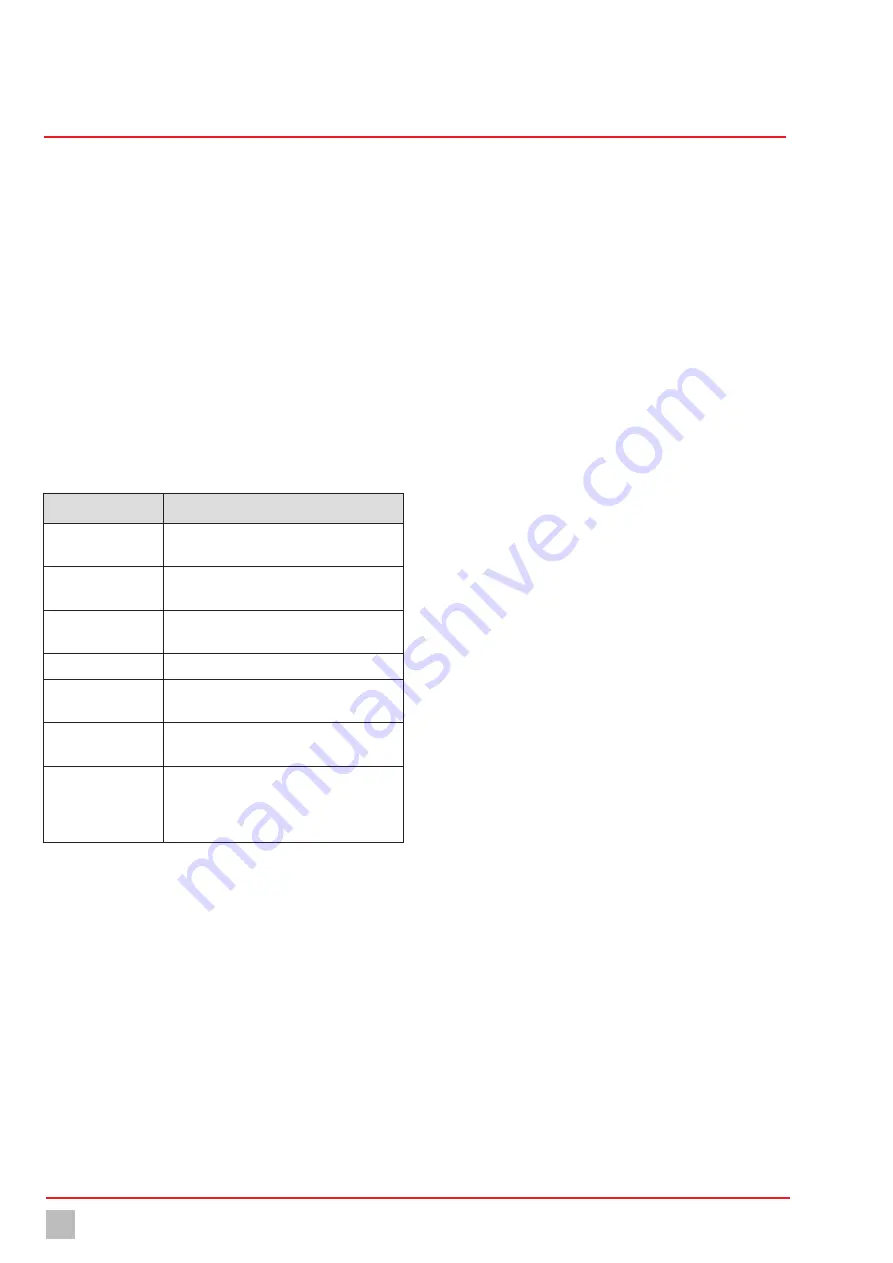

8.3.1.6 Digital inputs

You can use up to 8 digital inputs to evaluate switching statuses and to

detect them as alarm message which are to be documented in the log-

files.

Perform the following work steps:

1.

In the main menu under System > Inputs, navigate to the “Digital”

tab.

2.

In the “Digital” tab, configure the inputs and state the following infor-

mation.

3. Action:

Choose between “OK = open” (N.O., working contact) or “OK

= contact” (N.C., break contact).

4. Function:

Select a function from Tab. 38 „Functions digital inputs“

on page 32 depending on the desired reaction of your device to the

input.

ü

Configuration of the digital inputs completed.

Function

Reaction

Off

The switching of the contact has no influence

on the measurement or control.

Setpoint changeover

You can use the contact to switch between

reference sets.

Measuring water

shortage

All controller outputs will be switched off.

External stop

All controller outputs will be switched off.

Pre-alarm 1 − 4

Only display as an alarm message. Nothing is

switched off.

Main alarm 1 – 4

The appendant controller output is switched

off. The other outputs remain unaffected.

Others

You can assign an individual name to this

digital input. The name is displayed in the

alarm messages during switching the

contacts.

Tab. 38: Functions digital inputs

8.3.2 Outputs

Depending on the equipment, you can connect a range of actors to the

device and actuate them. Make sure that you actuate the actor with the

correct signal type and select an appropriate output module with the con-

figuration.

An alarm relay, up to four analogue outputs and the possibility of connect-

ing external LEDs (e.g. for water sampling stations) are always available.

8.3.2.1 Controller outputs

You can configure and use up to four controllers.

Pre-conditions for actions:

ü

You have used the configuration assistant to assign an input and a

control function to a controller (see section 8.2 „Configuration assis-

tant“ on page 29).

Perform the following steps:

1.

Working in the main menu under System > Outputs, navigate to the

“Controller” tab.

2.

Working in the “Controller” tab, configure the controller output and

state the following information.

3. Y-alarm:

Activate the Y alarm. The Y alarm is a safety cut-out. If the

controller output power amounts to more than 95 % (e.g. through a

malfunction) over the set time, the Y alarm will be triggered and the

corresponding controller output will be set to 0 %. You can set a time

between 0 and 200 minutes.

4. Basic load:

Depending on the controller function, you can set a base

load which is always active independently of the control variable.

With a base load of 10 %, the actor is always actuated with a mini-

mum of 10 %.

5. Limit:

Depending on the controller function, you can set a limit of be-

tween 5 and 100 %. State the value at which the actor should be ac-

tuated as maximum.

6.

Further settings are dependant on the function of the controller. Fur-

ther information is available in Tab. 20 „Functions of the individual

controllers“ on page 17.

ü

Configuration of the controller outputs completed.

8.3.2.2 Actuation via a timer

The output can be used for direct actuation via a timer. This is required

e.g. to run the flocculant pump or the peristaltic pumps over a certain

time.

Pre-conditions for actions:

ü

You have assigned the "Timer switch" input to a controller using the

configuration wizard as described in the chapter 8.1 „First steps“ on

page 29.

Perform the following work steps:

1.

Working in the System menu, navigate to > Outputs and configure

the output (see section 8.3.2 „Outputs“ on page 32).

2.

Navigate to the menu > setpoints. Here, you can set the desired set

control output directly from 0 to 100 %.

3. Reference set:

Here, you can set various control outputs and via the

timers in the “Switching” tab, you can determine when the control

output should be changed. The checkmark must be set against

“Switch setpoints automatically”. Further information pertaining to

switching is found in section 9.6 „Setpoints and reference sets“ on

page 41.

ü

Actuation configured via a timer.

8.3.2.3 Controller parameters

You can configure the behaviour of the individual controller channels. Ex-

planations of the various functions can be found in Tab. 20 „Functions of

the individual controllers“ on page 17 and in section 18 „Glossary“ on

page 61.

Perform the following work steps:

1.

Working in the main menu under System > Controller, navigate to the

“parameter” tab.