User Manual Of EL7-EC** AC Servo

218

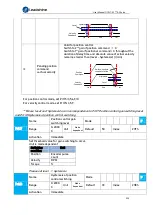

d)

Increase torque filter time

Pr1.00

Name

1

st

position loop gain

Mode

PP

HM

CS

P

Range

0~3000

0

Unit

0.1/s Default

320

Index

2100h

Activation

Immediate

Higher position loop gain value improves the responsiveness of the servo driver and lessens the

positioning time.

Position loop gain value shouldn’t exceed responsiveness of the mechanical system and take in

consideration velocity loop gain, if not it might cause vibration, mechanical noise and overtravel.

As velocity loop gain is based on position loop gain, please set both values accordingly.

Recommended range: 1.2

≤

Pr1.00/Pr1.01

≤

1.8

Pr1.02

Name

1

st

Integral Time Constant

of Velocity Loop

Mode

F

Range

1~10000 Unit

0.1ms Default

310

Index

2102h

Activation

Immediate

If auto gain adjusting function is not enabled, Pr1.02 is activated.

The lower the set value, the closer the lag error at stop to 0 but might cause vibration. If the

value set is overly large, overshoot, delay of positioning time duration and lowered

responsiveness might occur.

Set 10000 to deactivate Pr1.02.

Recommended range: 50000

≤

PA1.01xPA1.02

≤

150000

For example: Velocity loop gain Pr1.01=500(0.1Hz), which is 50Hz. Integral time constant of

velocity loop should be 100(0.1ms)

≤

Pr1.02

≤

300(0.1ms)

Pr1.04

Name

1

st

Torque Filter Time

Constant

Mode

F

Range

0~250

0

Unit

0.01ms Default

126

Index

2104h

Activation

Immediate

To set torque command low-pass filter, add a filter delay time constant to torque command and

filter out the high frequencies in the command.

Often used to reduce or eliminate some noise or vibration during motor operation, but it will

reduce the responsiveness of current loop, resulting in undermining velocity loop and position

loop control. Pr1.04 needs to match velocity loop gain.

Recommended range: 1,000,000/(2π×Pr1.04)

≥

Pr1.01×4

For example: Velocity loop gain Pr1.01=180(0.1Hz) which is 18Hz. Time constant of torque filter

should be Pr1.01

≤

221(0.01ms)

If mechanical vibration is due to servo driver, adjusting Pr1.04 might eliminate the vibration. The

smaller the value, the better the responsiveness but also subjected to machine conditions. If the

value is too large, it might lower the responsiveness of current loop.

With higher Pr1.01 value settings and no resonance, reduce Pr1.04 value;

With lower Pr1.01 value settings, increase Pr1.04 value to lower motor noise.