TP-6196 10/09

93

Section 6 Component Testing and Adjustment

6.12 Fuel Systems

Explosive fuel vapors.

Can cause severe injury or death.

Use extreme care when handling,

storing, and using fuels.

WARNING

The fuel supplier provides and maintains manual

shut-off valves and the primary regulator. Verify that the

fuel system capacity is adequate to supply the generator

set plus all other gas appliances.

A factory-installed secondary regulator and 12 VDC

solenoid valve are located in the front inlet air

compartment.

The controller energizes the

fuel

solenoid valve to open at startup and deenergizes the

valve to close at shutdown.

The secondary fuel

regulator reduces fuel pressure for delivery to the fuel

metering valve. The fuel flows from the fuel metering

valve to the carburetor in a gaseous state.

The

carburetor mixes the fuel with intake air for consumption

by the engine.

Use a universal exhaust gas oxygen (UEGO) sensor to

check the fuel mixture after replacing the fuel regulator,

fuel mixer, or silencer. The engine should be warm when

the fuel mixture is checked.

See Section 6.12.6 for

instructions to check the fuel mixture.

Refer

to

the

troubleshooting

instructions

in

Section 3,Troubleshooting, to identify generator set

operation problems that may be caused by an

inadequate fuel supply, incorrect adjustments, or

damaged fuel system components.

Then use the

instructions in this section to check fuel system

components.

6.12.1 Gas Piping

Verify that the gas pipe size meets the size

specifications in Figure 6-32. Measure the pipe length

from the gas utility pressure regulator to the end of the

pipe where it connects to the fuel inlet of the generator

set.

Add 2.4 m (8 ft.) for each bend in the pipe.

Compare the total length with the chart in Figure 6-32. If

the piping is longer than the maximum length shown in

the chart, replace it with a larger pipe size. Bleed the air

from the gas lines after installation.

Figure 6-33 lists the maximum gas flow rates for each

model.

Pipe Length,

m (ft.)

8.5RES

12RES

Natural

Gas

LP

Natural

Gas

LP

8

(25)

3/4

1/2

3/4

3/4

15

(50)

3/4

3/4

1

1

30

(100)

1

1

1

1

46

(150)

1

1

1 1/4

1

61

(200)

1

1

1 1/4

1 1/4

Figure 6-32

Maximum Gas Pipe Length

Generator Set Model

Gas Flow Rate, Btu/hr.

Natural Gas

LP

8.5kW

132000

180000

12kW

202000

270000

Figure 6-33

Maximum Natural Gas Flow Rate

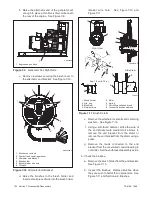

6.12.2 Fuel Solenoid Valve

A solenoid valve upstream of the regulator and the

flexible fuel connector provides automatic fuel on/off

control. The engine starting battery powers the solenoid

valve and the engine starting controls open the valve

when the engine cranks or runs.

Gas Valve Operation Test Procedure

1. Disconnect the positive (+) battery lead from the

gas valve terminal.

2. Apply 12 VDC to the gas valve terminal and listen

for an audible click, indicating that the valve

actuates.

3. Replace the gas valve if it does not actuate in

step 2.

6.12.3 Fuel Regulators

The typical gaseous fuel system uses two regulators.

The primary regulator reduces the line pressure to an

allowable inlet pressure for the secondary regulator.

The fuel supplier provides and maintains the primary

regulator. The secondary regulator is factory-installed

on the generator set and is designed for a maximum inlet

pressure of 2.7 kPa (6 oz./in.

2

) or 280 mm (11 in.) water

column.

Note:

Do not attempt to adjust the fuel mixture or engine

speed by adjusting the regulators.

Summary of Contents for 12RES

Page 2: ......

Page 6: ...TP 6196 10 09 6 Notes ...

Page 34: ...TP 6196 10 09 34 Section 3 Troubleshooting Notes ...

Page 52: ...TP 6196 10 09 52 Section 4 ADC 2100 and DC 2200 Controllers Notes ...

Page 72: ...TP 6196 10 09 72 Section 5 ADC RES and DC RET Controller Notes ...

Page 100: ...TP 6196 10 09 100 Section 6 Component Testing and Adjustment Notes ...

Page 131: ......