TP-6196 10/09

21

Section 2 Scheduled Maintenance

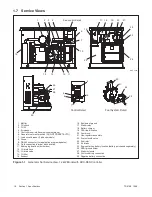

2.2 Lubrication System

See Section 2.1, Service Schedule, for oil change and

oil filter replacement intervals. See Figure 2-2 for the oil

drain, oil check, oil fill, and oil filter locations.

The engine has a positive pressure lubrication system

and low oil pressure shutdown.

1. Dip stick location

2. Oil fill

3. Oil drain hose

4. Oil drain valve

5. Oil cooler

6. Oil filter

ADV--7466

3

2

6

4

5

1

Figure 2-2

Lubrication System (typical)

2.2.1

Low Oil Pressure Shutdown

The low oil pressure shutdown feature protects the

engine against internal damage if the oil pressure drops

below preset limits because of oil pump failure or other

malfunction. It does not protect against damage caused

by operating with the oil level below the safe range—it is

not a low oil level shutdown.

2.2.2

Oil Level Check

Check the oil level regularly and add oil as needed to

protect against running out of oil. See Figure 2-2 for the

dipstick and oil fill locations. Do not check the oil level

when the generator set is running.

Shut down the

generator set and wait several minutes before checking

the oil level.

2.2.3

Engine Oil Recommendation

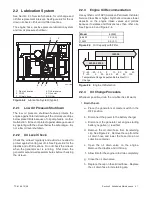

Use synthetic oil of API (American Petroleum Institute)

Service Class SG or higher. Synthetic oil causes fewer

deposits on the engine intake valves and pistons

because it oxidizes and thickens less than other oils.

See Figure 2-3 and Figure 2-4.

Model

L (Qt.)

8.5kW

1.9 (2.0)

12kW

2.0 (2.1)

Figure 2-3

Oil Capacity with Filter

°

C

°

F

--30

--20

--10

0

10

20

30

40

0

20

40

Temperature Range Expected Before Next Oil

Change

32

60

80

100

10W-30

5W-20, 5W-30

--20

Figure 2-4

Engine Oil Selection

2.2.4

Oil Change Procedure

Whenever possible, drain the oil while it is still warm.

1.

Drain the oil.

a. Place the generator set master switch in the

OFF position.

b. Disconnect the power to the battery charger.

c. Disconnect the generator set engine starting

battery, negative (--) lead first.

d. Remove the oil drain hose from its retaining

clip. See Figure 2-2. Remove the cap from the

oil drain hose and lower the hose into an oil

collection container.

e. Open the oil drain valve on the engine.

Remove the dipstick and oil fill cap.

f. Allow time for the engine oil to drain completely.

g. Close the oil drain valve.

h. Replace the cap on the oil drain hose. Replace

the oil drain hose in its retaining clip.

Summary of Contents for 12RES

Page 2: ......

Page 6: ...TP 6196 10 09 6 Notes ...

Page 34: ...TP 6196 10 09 34 Section 3 Troubleshooting Notes ...

Page 52: ...TP 6196 10 09 52 Section 4 ADC 2100 and DC 2200 Controllers Notes ...

Page 72: ...TP 6196 10 09 72 Section 5 ADC RES and DC RET Controller Notes ...

Page 100: ...TP 6196 10 09 100 Section 6 Component Testing and Adjustment Notes ...

Page 131: ......