TP-6196 10/09

96

Section 6 Component Testing and Adjustment

11. Connect and turn on the new fuel supply.

12. Check that the generator set master switch is in the

OFF position.

13. Reconnect the generator set engine starting

battery leads, negative (--) lead last.

14. Reconnect power to the battery charger.

15. Start the generator set by moving the generator set

master switch to the RUN position.

16. Check for leaks using a gas leak detector.

17. Move the generator set master switch to the AUTO

position.

To convert from LP vapor to natural gas, follow the same

fuel conversion procedure, moving the hose fitting to the

natural gas port and plugging the LP port.

For the

12kWmodel, disconnect the DSAI leads for LP vapor.

See Figure 6-37.

6.12.5 Digital Spark Advance Ignition

The digital spark advance ignition (DSAI) on the Model

12kWoptimizes the engine timing for the selected fuel,

natural gas or LP. The location of the DSAI leads is

shown in Figure 6-36. Connect the DSAI leads in the air

intake compartment together for natural gas fuel.

Disconnect the leads if LP is used. See Figure 6-37.

See the engine service manual for DSAI service

information.

6.12.6 Fuel Metering Valve Adjustment

The fuel system is factory-adjusted to comply with

applicable emission standards and to provide the best

possible hot and cold starting.

Note:

Adjusting the fuel metering valves on emissions-

certified generator sets may void the emission

certification.

Use a universal exhaust gas oxygen (UEGO) sensor to

check the fuel mixture after replacing the fuel regulator,

carburetor, or silencer. Use the following procedure to

check the fuel mixture after the engine has reached

normal operating temperature.

The fuel metering valves are sealed to prevent field

adjustments.

If the fuel metering valve requires

adjustment, do not break the seals on the fuel metering

valve.

Obtain a new fuel metering valve from the

manufacturer and replace the sealed valve with the new

part.

See Figure 6-36 for the fuel metering valve

location. Refer to the generator set Parts Catalog for the

fuel metering valve part number.

Only trained, authorized service technicians may adjust

the new fuel metering valve. The adjustment procedure

requires a digital volt meter (DVM), UEGO oxygen

sensor service kit GM29385, and a load bank capable of

the rated kW for the fuel being used. Always use an

oxygen sensor when adjusting the fuel metering valves.

Observe

the

following

safety

precautions

while

performing the procedure.

Hot engine and exhaust system.

Can cause severe injury or death.

Do not work on the generator set until

it cools.

WARNING

Servicing the exhaust system.

Hot parts can cause

severe injury or death.

Do not touch hot engine parts. The

engine and exhaust system components become extremely

hot during operation.

Fuel Mixture Check/Fuel Metering Valve

Adjustment Procedure

1. Place the generator set master switch in the OFF

position.

2. Disconnect power to the battery charger.

3. Remove the oxygen sensor plug from the exhaust

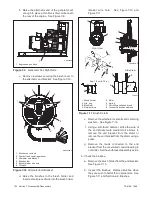

manifold and install the oxygen sensor.

See

Figure 6-38 for location.

1

GM29253

1. Oxygen sensor mounting location

Figure 6-38

Oxygen Sensor Mounting Location

Summary of Contents for 12RES

Page 2: ......

Page 6: ...TP 6196 10 09 6 Notes ...

Page 34: ...TP 6196 10 09 34 Section 3 Troubleshooting Notes ...

Page 52: ...TP 6196 10 09 52 Section 4 ADC 2100 and DC 2200 Controllers Notes ...

Page 72: ...TP 6196 10 09 72 Section 5 ADC RES and DC RET Controller Notes ...

Page 100: ...TP 6196 10 09 100 Section 6 Component Testing and Adjustment Notes ...

Page 131: ......