UPS5000-E-(350 kVA-800 kVA)

User Manual (50 kVA Power Modules)

B Menu Hierarchy

Issue 05 (2018-01-08)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

292

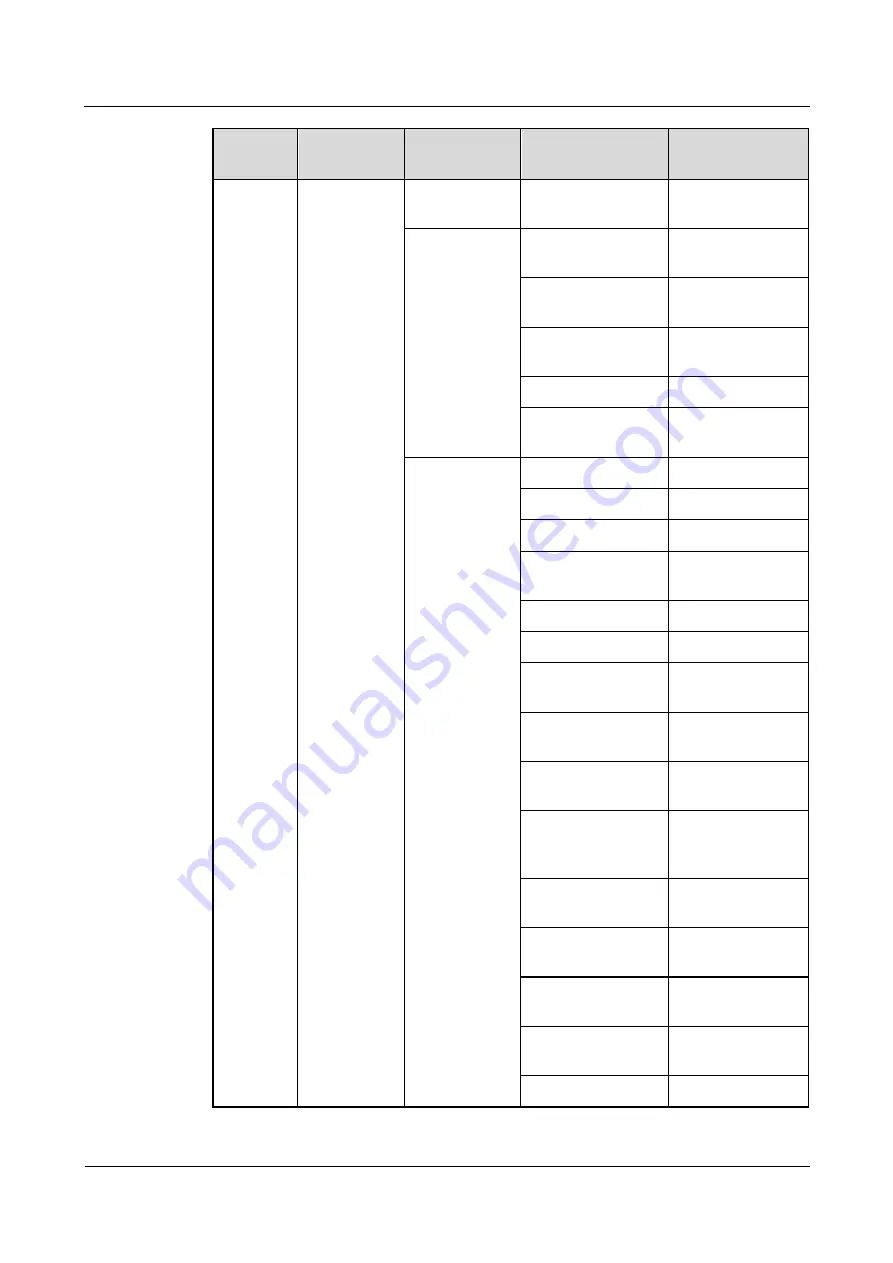

Level–1

Menu

Level–2

Menu

Level–3

Menu

Level–4 Menu

Level–5 Menu

Max. BPM transfer

times

N/A

Bypass Param.

Bypass frequency

range

N/A

Maximum bypass

voltage

N/A

Minimum bypass

voltage

N/A

ECO voltage range

N/A

BPM mode upon

BPM overtemp

N/A

Battery Param.

Installation time

N/A

Maintenance period

N/A

Battery type

N/A

Chg. cur. limiting

coef.

N/A

Cell float voltage

N/A

Cell equalized volt

N/A

Transfer-to-equalize

d charging cur. coef.

N/A

SOC to start

equalized charging

N/A

Automatic equalized

charging

N/A

Forced equalized

charging protection

time

N/A

Equalized charging

protection interval

N/A

Scheduled equalized

charging interval

N/A

Float volt. temp.

comp.

N/A

Float volt. temp.

comp. coef.

N/A

Max batt. dis.time

N/A