25

9. Setting up

9.1 Swashplate linkage

The first procedure is to adjust the four-servo swashplate linkage:

•

First set the servos to centre by switching on the radio system with the collective pitch stick

at centre. Fit the output arms correctly on the servos, and fine-tune the settings using your

transmitter’s servo centre adjustment facility if required.

•

At the centre position of the servos the output arms on the roll / collective pitch servos

should be exactly vertical, while the bellcrank arms connected to the pushrods running to

the swashplate must be exactly horizontal. This has to be set by adjusting the four vertical

pushrods. First disconnect one pushrod from the swashplate, then set the swashplate hori-

zontal by adjusting the remaining three pushrods. Now adjust the length of the fourth

(disconnected) pushrod so that it can be re-connected to the swashplate without exerting

any force at all on the servo.

•

The direction of servo rotation, and therefore the working “sense” of the components in the

swashplate mixer (pitch-axis, roll, collective pitch) must now be set correctly; for this set-up

process it is again useful temporarily to disconnect one of the pushrods running to the

swashplate:

When you increase collective pitch, all the pushrods should move upward, thereby moving

the swashplate in the axial direction. If one of the servos rotates in the wrong direction,

correct it using the

servo reverse

facility on your transmitter.

When you apply forward cyclic, i.e. a pitch-axis command in the forward direction, the

swashplate should tilt forward; if it tilts to the rear, you need to reverse the

pitch-axis

function in the swashplate mixer

.

When you apply a right-roll command, the swashplate should tilt to the right. If it inclines to

the left, you must reverse the

roll function in the swashplate mixer

.

9.2 Setting up the cyclic control system

The basic settings of the roll and pitch-axis control systems should already be correct if you

have fitted the pushrods exactly as described in these instructions. The pushrod linkage points

on the servo output arms are pre-defined, so any servo travel adjustment required must be car-

ried out via the transmitter’s electronic adjustment facilities. Please note that servo travel must

not be set at too high a value; the swashplate must not foul the main rotor head when the roll

and pitch-axis stick is at its end-points, as this would mean that smooth collective pitch control

would no longer be possible, since the swashplate could not move any further along the shaft.

9.3 Main rotor collective pitch settings

The collective pitch values are measured using a rotor blade pitch gauge (not included in the

kit). The following table shows good starting points; the optimum values may vary according to

the rotor blades you are using and the model itself.

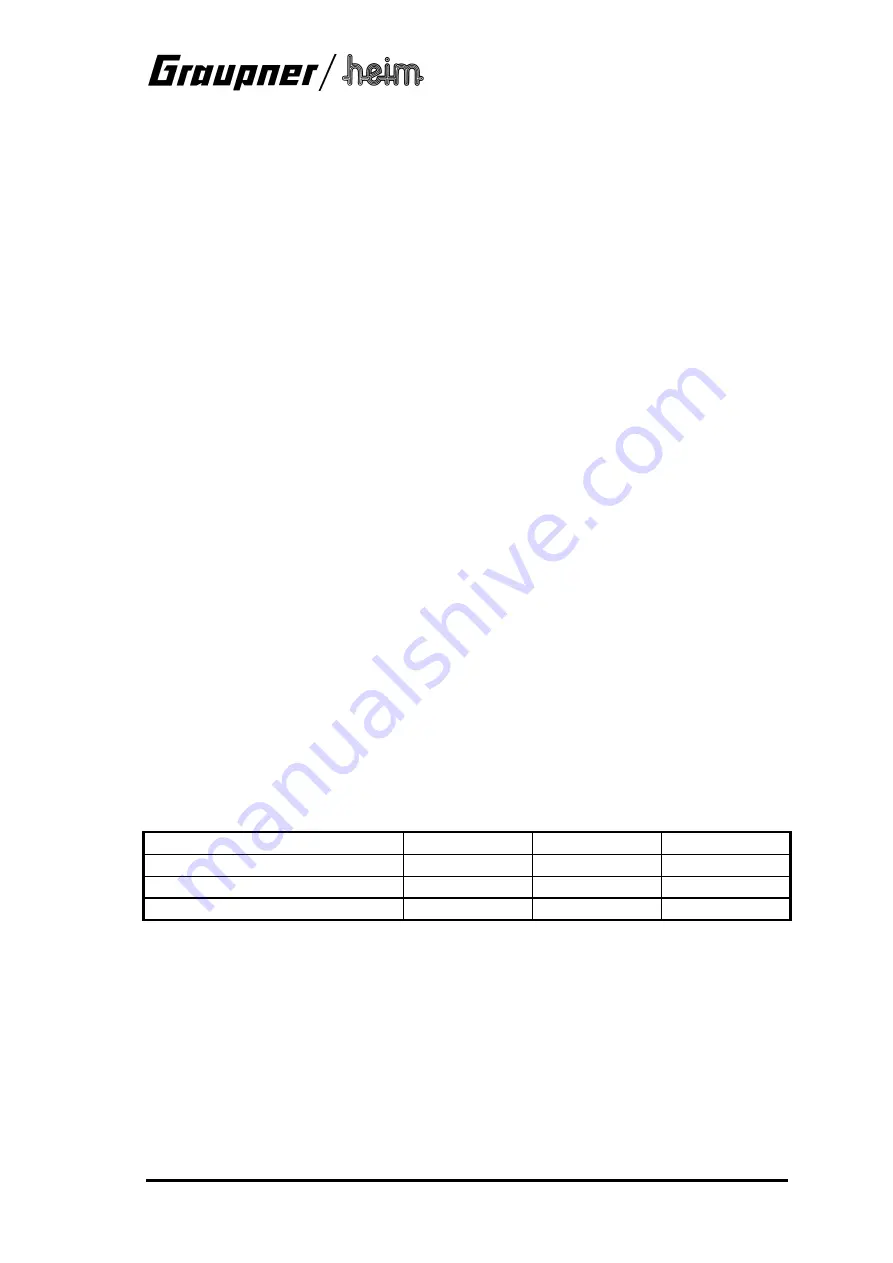

Minimum

Hovering point

Maximum

Hover

+1°

9...10°

18°

Cruise

+1°

8...9°

18°

Auto-rotation

+1°

10°

18°

The collective pitch settings are adjusted at the transmitter. This is the procedure:

1. Measure the setting for hovering collective pitch and set it correctly.

2. Measure collective pitch maximum and minimum, and adjust the values using the collective

pitch adjustment facility on your transmitter.