Part No. 139378

Z-30/20N • Z-30/20N RJ • Z-34/22 • Z-34/22N

3 - 1

Section 3 • Scheduled Maintenance Procedures

June 2011

Scheduled Maintenance Procedures

About This Section

This section contains detailed procedures for each

scheduled maintenance inspection.

Each procedure includes a description, safety

warnings and step-by-step instructions.

Symbols Legend

Safety alert symbol—used to alert

personnel to potential personal

injury hazards. Obey all safety

messages that follow this symbol

to avoid possible injury or death.

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided,

could result in death or serious

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may cause minor or moderate

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may result in property damage.

Indicates that a specific result is expected after

performing a series of steps.

Indicates that an incorrect result has occurred

after performing a series of steps.

Observe and Obey:

Maintenance inspections shall be completed by

a person trained and qualified on the

maintenance of this machine.

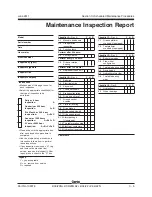

Scheduled maintenance inspections shall be

completed daily, quarterly, six months, annually

and every 2 years as specified on the

Maintenance Inspection Report.

Failure to properly complete each

inspection when required could

result in death, serious injury or

substantial machine damage.

Immediately tag and remove from service a

damaged or malfunctioning machine.

Repair any machine damage or malfunction

before operating machine.

Use only Genie approved replacement parts.

Machines that have been out of service for a

period longer than 3 months must complete the

quarterly inspection.

Unless otherwise specified, perform each

procedure with the machine in the following

configuration:

• Machine parked on a firm, level surface

• Boom in the stowed position

• Turntable rotated with the boom between the

non-steer wheels

• Key switch in the off position with the

key removed

• Wheels chocked

• All external AC power supply disconnected

from the machine

Summary of Contents for Z-30/20N

Page 1: ......

Page 148: ...6 46 June2011 Section 6 Schematics 6 45 Power Cable Wiring Diagram...

Page 149: ...6 47 Section 6 Schematics June2011 6 48 Drive Contactor Panel Wiring Diagram...

Page 152: ...6 50 June2011 Section 6 Schematics Manifold and Limit Switch Wiring Diagram 6 49...

Page 153: ...6 51 Section 6 Schematics June2011 6 52 LVI BCI Option Wiring Diagram...

Page 156: ...6 54 June2011 Section 6 Schematics 6 53 Charger Interlock Option...

Page 157: ...6 55 Section 6 Schematics June2011 6 56 CTE Option CE Models...

Page 160: ...6 58 June2011 Section 6 Schematics Hydraulic Schematic 6 57...