4 - 26

Z-30/20N • Z-30/20N RJ • Z-34/22 • Z-34/22N

Part No. 139378

June 2011

Section 4 • Repair Procedures

REV A

SECONDARY BOOM COMPONENTS

40 Attach a lifting strap from an overhead crane to

the upper secondary boom.

41 Remove the pin retaining fastener from the

mid-pivot to upper secondary boom pivot pin.

Use a soft metal drift to remove the pin.

42 Remove the upper secondary boom with

compression link from the machine.

Crushing hazard. The upper

secondary boom with

compression link could become

unbalanced and fall when

removed from the machine if not

properly supported by the

overhead crane.

43

Z-30N and Z-30N RJ: Remove

the mounting

fasteners from the counterweight attached to

the lower leveling link.

44

Z-30N and Z-30N RJ: Attach

a lifting strap from

an overhead crane to the counterweight.

Remove the counterweight from the lower

leveling link.

Tip-over hazard. The counterweight

is critical to machine stability. If

the counterweight is not installed

during reassembly of the machine,

the machine will become unstable

and tip over.

Crushing hazard. The

counterweight could become

unbalanced and fall when

removed from the machine if not

properly supported by the overhead

crane.

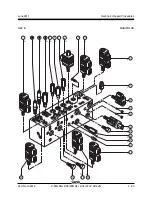

45 Remove the mounting fasteners from the

function manifold and slide the function manifold

to the side. This will allow access to the

secondary boom lift cylinder barrel-end pivot

pin.

46 Remove the mounting fasteners from the

auxiliary power unit. Do not disconnect the

electrical cables or hydraulic hoses.

47 Slide the auxiliary power unit to the side to

access the other secondary boom lift cylinder

barrel-end pivot pin.

48 Remove the retaining fasteners from the

secondary boom lift cylinder barrel-end pivot

pins.

49 Attach a lifting strap from an overhead crane to

the lug on the rod end of the secondary boom

lift cylinder.

50 Tag, disconnect and plug the hydraulic hoses

from the secondary boom lift cylinder. Cap the

fittings on the cylinder.

Bodily injury hazard. Spraying

hydraulic oil can penetrate and

burn skin. Loosen hydraulic

connections very slowly to allow

the oil pressure to dissipate

gradually. Do not allow oil to squirt

or spray.

51 Use a slide hammer to remove the barrel-end

pivot pins (access the pins from the access

holes in the bulkheads, one on each side).

Remove the secondary boom lift cylinder from

the machine.

Crushing hazard. The secondary

boom lift cylinder could become

unbalanced and fall when

removed from the machine if not

properly supported by the overhead

crane.

Summary of Contents for Z-30/20N

Page 1: ......

Page 148: ...6 46 June2011 Section 6 Schematics 6 45 Power Cable Wiring Diagram...

Page 149: ...6 47 Section 6 Schematics June2011 6 48 Drive Contactor Panel Wiring Diagram...

Page 152: ...6 50 June2011 Section 6 Schematics Manifold and Limit Switch Wiring Diagram 6 49...

Page 153: ...6 51 Section 6 Schematics June2011 6 52 LVI BCI Option Wiring Diagram...

Page 156: ...6 54 June2011 Section 6 Schematics 6 53 Charger Interlock Option...

Page 157: ...6 55 Section 6 Schematics June2011 6 56 CTE Option CE Models...

Page 160: ...6 58 June2011 Section 6 Schematics Hydraulic Schematic 6 57...