16

17

19

18

C4000I

23

532100 - Rev.A

2

2

1

4

3

M4 x 12 UNI 5933 DIN 7991

M4 UNI 5588 DIN 934

2.5

7

Tr

ansla

tion of the original instruc

tions

ENGLISH

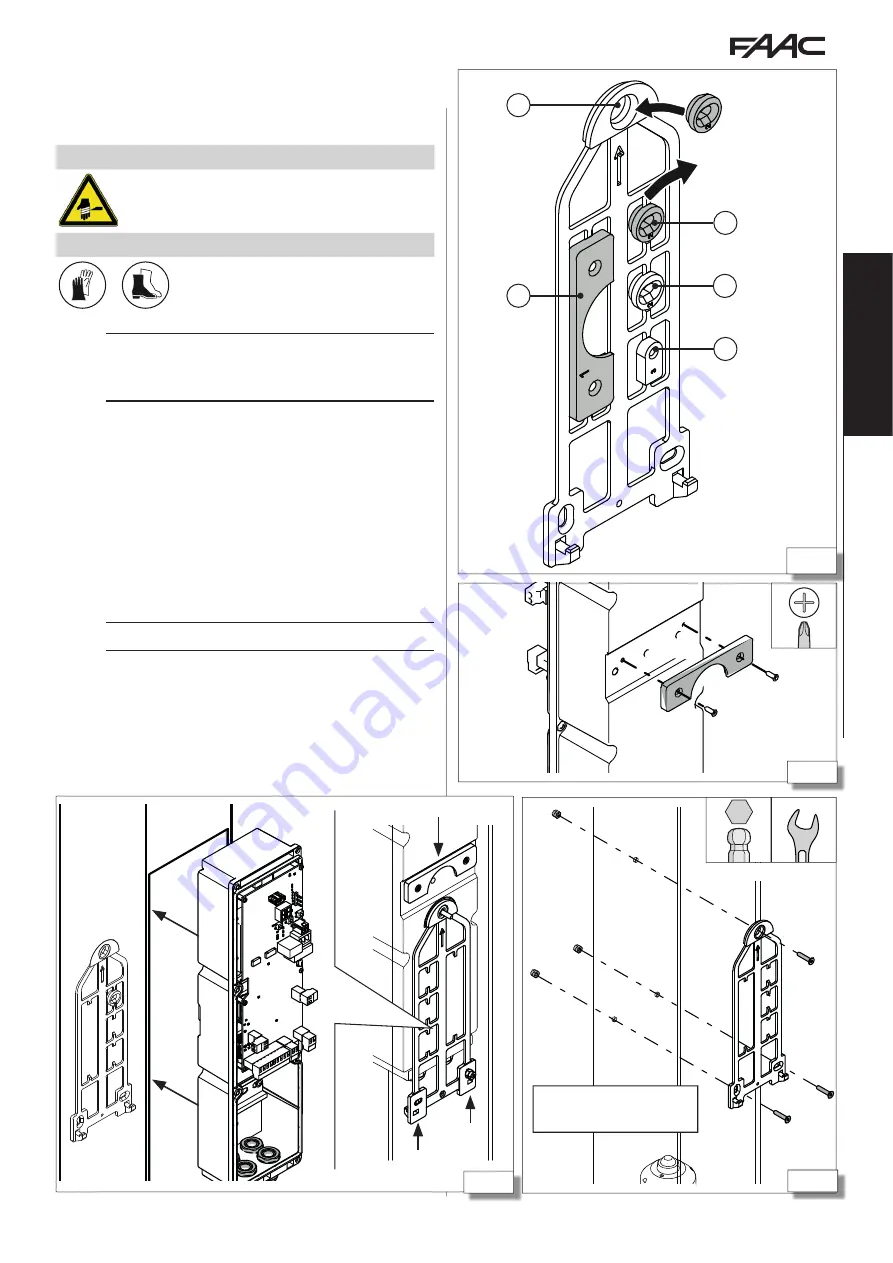

5.5 INSTALL THE ELECTRONIC BOARD

ENCLOSURE

WITH ENCLOSURE MOUNTING BRACKET

RISKS

PERSONAL PROTECTIVE EQUIPMENT

The enclosure mounting bracket can only be installed

on columns having internal dimensions greater than

110x113 (LxP).

1.

16

Remove the bushes

2

, the mounting bracket

fitting

1

and the emergency battery fitting

3

. Keep

them to one side for the following procedures.

2. Insert the bush

2

into the housing

4

.

3. Fasten the mounting bracket fitting

1

(

17

-1)

onto the base of the enclosure using the 2 screws

provided.

4. Fasten the mounting bracket to the column using

the previously drilled holes with 3 screws and 3

nuts (not supplied) (

18

).

Install it with the arrow facing upwards.

5. Insert the enclosure and rest it against the column.

Then move it downwards and slide it onto the 3

mounting points (

19

).