CAM216/16 IOM

Doc. Number: ECM-402-0116

January 2016, Rev. 1

25

Section 4: HART Quick Setup and Actuator Options

HART Quick Setup and Actuator Options

Section 4: HART Quick Setup and

Actuator Options

The Emerson Process Management Electric Actuators must have mechanical valve travel and

torque switches set first. Refer to Manual E796 to perform these adjustments.

4.1

M2CP-320B Quick Setup Instructions

The M2CP-320B is factory configured as specified by the customer purchase order. If field setup

changes are required, follow the setup instructions as mentioned below.

1.

Entering Setup Mode:

Locate DIP switches SW1, SW2, and SW3 (Execute button) on the DCM 320B

board and make a note of the original configuration of the switches before making

modifications. SW1 selects mode, SW2 selects respective setup parameters and SW3

sends the changed configuration. Place the selector switch in the OFF position and

select desired setup mode by setting SW2. Please refer to Controlinc Quick Startup

Guide for DCM320B. If done correctly, you will see a rapid flashing

CPU GOOD indicator.

2.

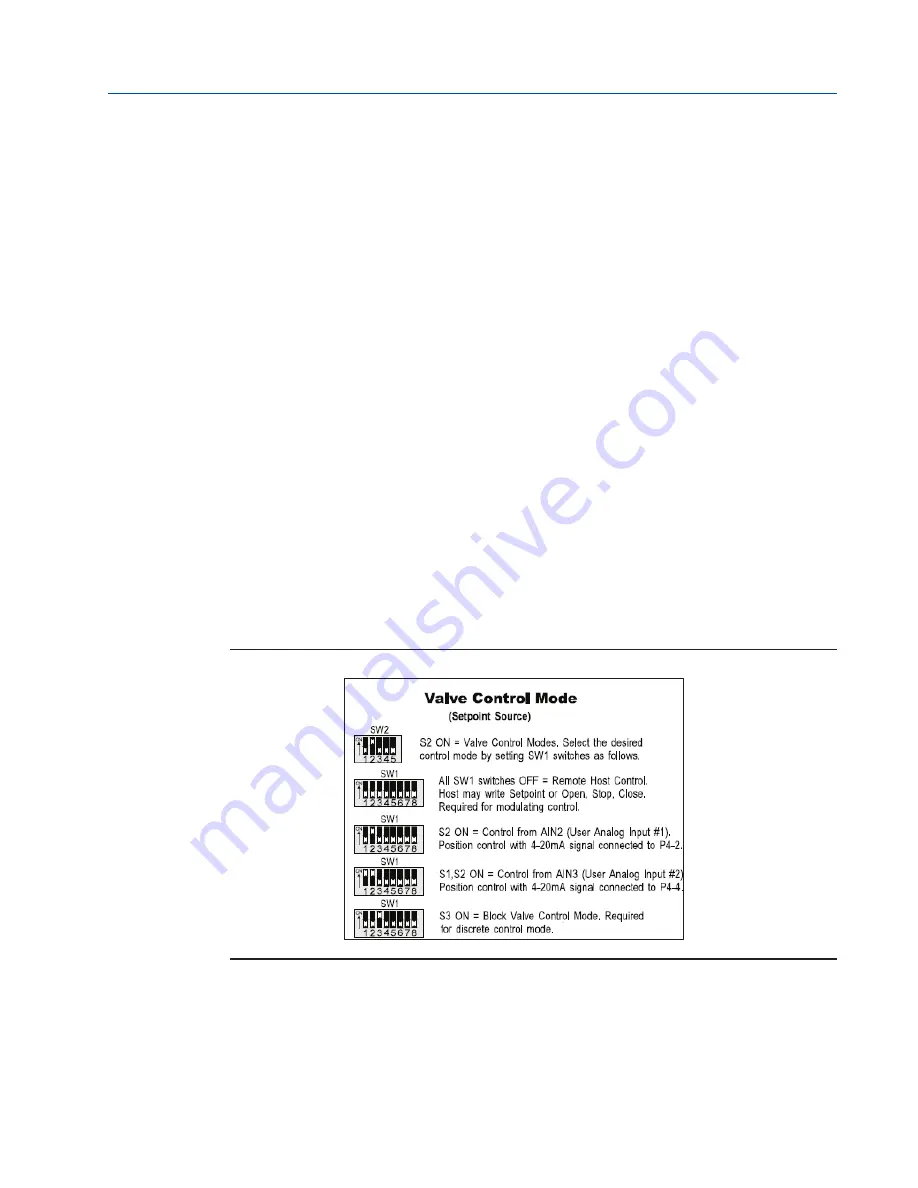

Valve Control Mode:

Enter the following configuration on SW1 and SW2 to change the Valve

Control settings:

Set both SW1 and SW2 switches as indicated below and press the execute button to

store the setup parameter to non-volatile memory.

Figure 31

Valve Control Mode Switch Settings

3.

Exiting Setup Mode:

To exit Setup mode, place SW1 and SW2 back to the original configuration and press

the execute button. If successful, CPU GOOD will return to a slow and steady flashing.