Before Use

6

Disclaimer

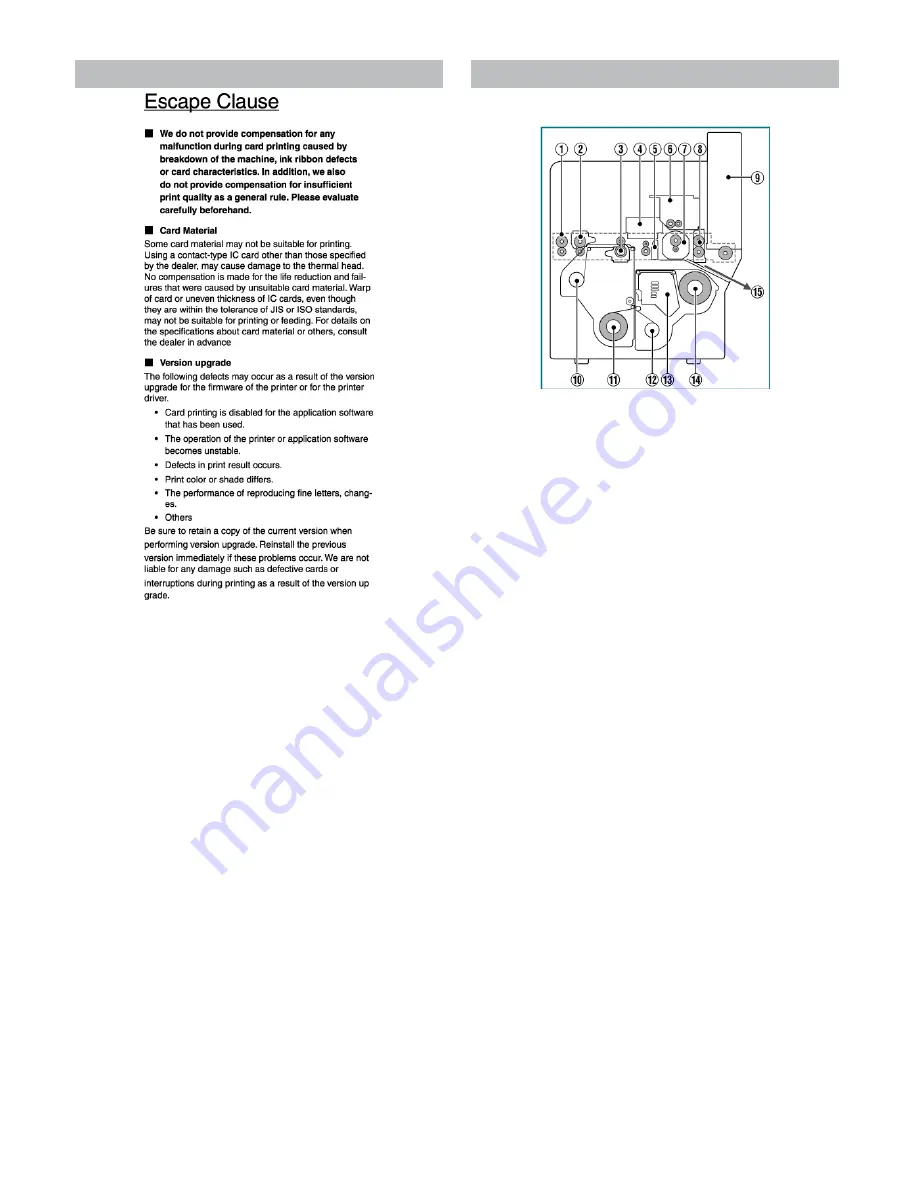

Name and functions of parts

Internal mechanism diagram

①

Card feeder unit

●

This is the roller for feeding cards. Each of the feed rollers needs to

be cleaned daily.

②

Warpage correction heating roller

●

Some types of cards may warp. Adjust accordingly until warpage is

eliminated. Set using the host computer.

③

Retransfer heating roller

●

You can adjust the temperature and retransfer time for some retrans-

fer films and cards. Set using the host computer.

④

Non-contact IC encoder

●

You can adjust the position to stop the card when a non-contact IC

card is used. Set using the host computer.

⑤

Contact IC

●

You can adjust the position to stop the card when a contact IC card

is used. Set using the host computer.

⑥

Magnetic encoder

●

You can select the coercivity when writing data to the magnetic stripe

card. Set using the host computer.

⑦

Card turnover unit

●

Inverts the card.

⑧

Cleaning roller

●

Removes any dust or dirt attached to the card. The cleaning roller

needs to be cleaned daily.

⑨

Card hopper

●

For loading cards.

⑩

Retransfer film (take-up side)

●

For attaching the take-up side of the retransfer film.

⑪

Retransfer film (supply side)

●

For attaching the unused side of the retransfer film.

⑫

Ink ribbon (take-up side)

●

For attaching the take-up side of the ink ribbon.

⑬

Thermal head

●

The thermal head is a consumable part. For details on its replace-

ment, please consult our authorized dealers.

⑭

Ink ribbon (supply side)

●

For attaching the unused side of the ink ribbon.

⑮

NG card outlet

●

Discharges NG cards, such as during card jams.

Summary of Contents for EDIsecure X ID 8300

Page 14: ...14 Operation ...

Page 15: ...15 Operation ...