© Danfoss | August 2018

AQ00000211 |

157

ENGINEERING TOMORROW

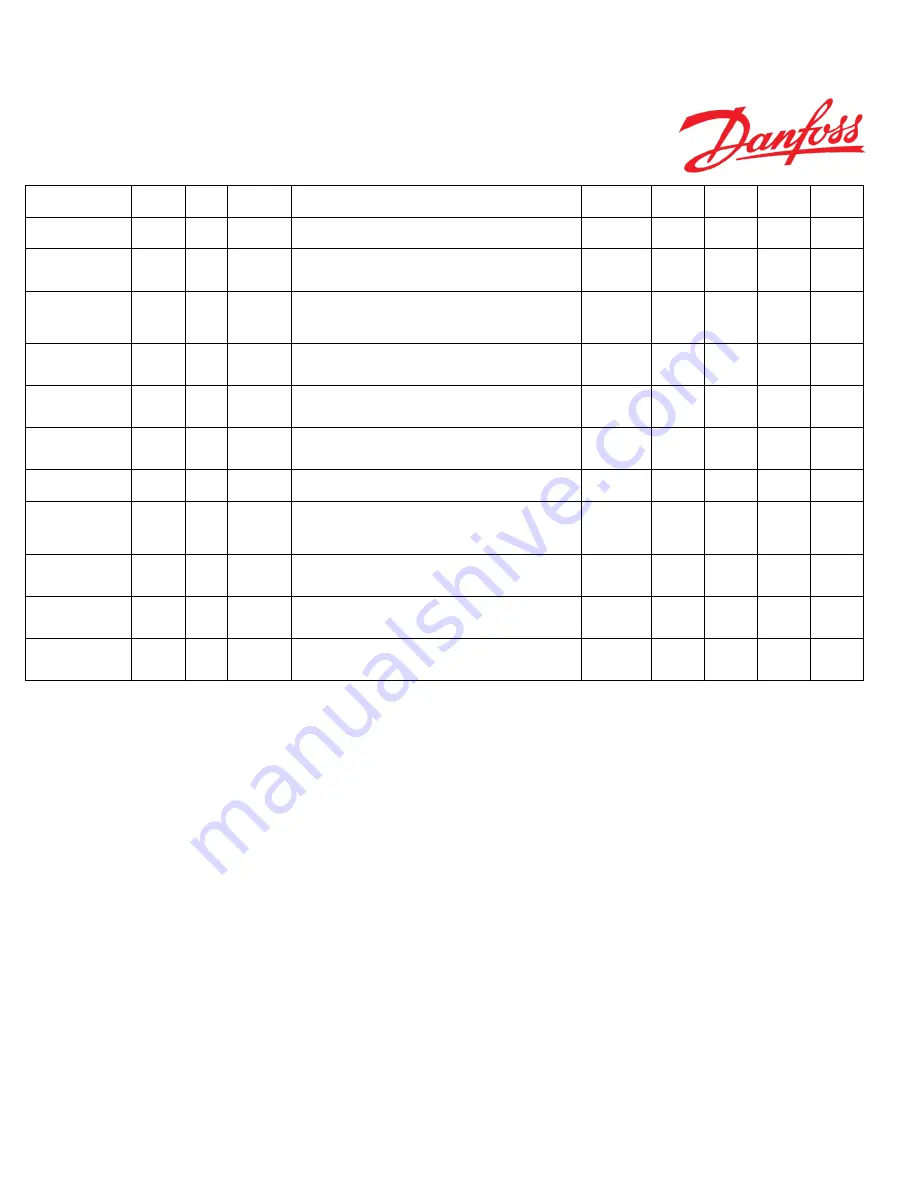

Spool monitoring - Max

“spool out of control”

tolerance time

P3379

U16

x10mSec

Maximum timeout value used by spool monitoring algorithm

OEM

100

400

100

S

Spool monitoring –

confidence time

decrease rate

P3381

U16

-

Spool Monitoring time constant

OEM

0

60000

8000

S

Channel cross-check

monitoring - max Road

switch position

divergence time

P3383

U8

x10mSec

Timeout value for Safe ON-ROAD switch position, cross check between

MAIN- and SAFETY-controller. Resolution: 1 x10mSec = 10ms

OEM

0

255

10

S

Scaled Analogue sensor

limit offset

P3384

U16

IR

The analogue sensor output conversions to internal resolution [IR] is

limited to ±1000, based on the calibration parameters.

But internally it is checked that the un-clamped analogue sensor signal

does not exceeds the range:

(-1000 – P3384 [IR]) < “un-clamped analogue

sensor signal” <(1000 + P3384 [IR])

OEM

0

1000

50

S

Severity level for

temperature monitoring

P3386

U8

-

Severity Level for temperature monitoring

Valid Values:

0 (Severity level: Critical)

255 (Severity level: INFO)

OEM

0

255

0

Channel cross-check

monitoring - Max AUX

joystick engage

divergence time

P3387

U8

x10mSec

Maximum allowable time for which AUX Joystick Enable signals between

MAIN and SAFETY micro-controllers are allowed to be different

OEM

0

255

10

S

Channel cross-check

monitoring - Max AUX

joystick trim divergence

time

P3388

U8

x10mSec

Maximum allowable time for which AUX Joystick Trim signals between

MAIN and SAFETY micro-controllers are allowed to be different

OEM

0

255

10

S

Channel cross-check

monitoring - Max AUX

joystick trim divergence

P3389

U8

IR

Max allowable AUX Joystick Trim difference between MAIN and

SAFETY micro-controllers

OEM

0

255

50

S

Wheel angle limit offset

(CAN WAS)

P3390

U16

IR

The CAN Wheel angle sensor output conversions to internal resolution [IR]

is limited to ±1000 IR, based on the calibration parameters.

But internally it is checked that the un-clamped CAN Wheel angle sensor

signal does not exceeds the range: (-1000 – P3390 [IR]) < “un-clamped

analogue sensor signal” <(1000 + P3390 [IR])

OEM

0

1000

50

S

Channel cross-check

monitoring - Max WAS

auto-calibrated cylinder

stroke volume difference

P3392

U16

ccm

Maximum WAS Auto-calibrated Cylinder Stroke Volume Difference

OEM

1

10000

50

Channel cross-check

monitoring - Max WAS

auto-calibrated wheel

angle difference

P3394

U8

deg

Maximum WAS Auto-calibrated wheel angle Difference

OEM

1

89

3

Channel cross-check

monitoring - Max IMD

STW status divergence

time

P3395

U8

x10mSec

Maximum allowable time for which IMD STW Status between MAIN and

SAFETY micro-controllers are allowed to be different

OEM

0

255

10

S

Table 71

Summary of Contents for PVED-CLS

Page 6: ...6 Danfoss August 2018 AQ00000211 ENGINEERING TOMORROW ...

Page 71: ... Danfoss August 2018 AQ00000211 71 ENGINEERING TOMORROW Figure 29 ...

Page 127: ... Danfoss August 2018 AQ00000211 127 ENGINEERING TOMORROW ...

Page 147: ... Danfoss August 2018 AQ00000211 147 ENGINEERING TOMORROW ...

Page 182: ...182 Danfoss August 2018 AQ00000211 ENGINEERING TOMORROW ...