142 | © Danfoss | August 2018

AQ00000211

ENGINEERING TOMORROW

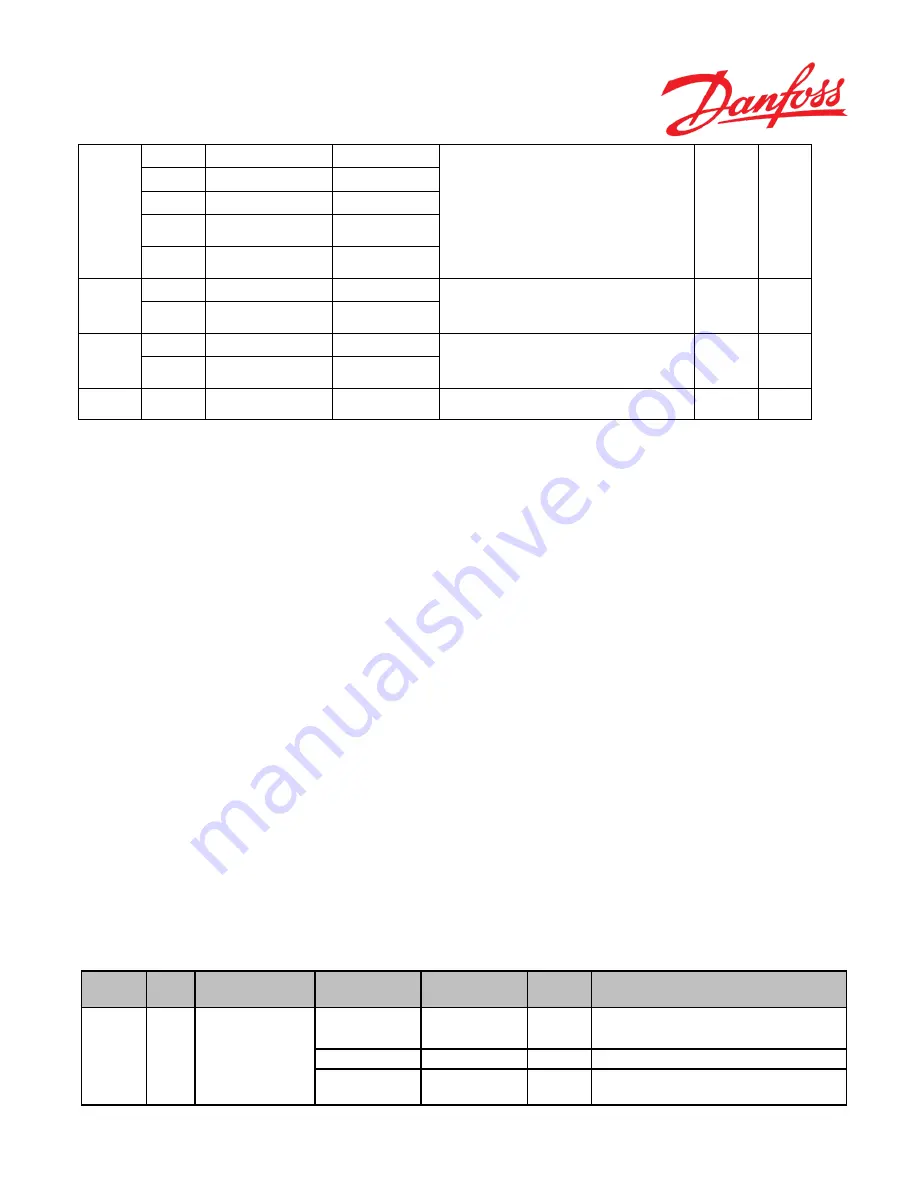

24

3426

Maximum steer angle, left

Vehicle Geometry

If WAS interface (P3244) = CAN:

Maximum steer angle, left (P3426)≤ 89 & Maximum steer angle,

right (P3428)≤ 89, Or

Automatically adjusted maximum steer angle to left side (CAN

WAS) (P3193)≤ 89 & Automatically adjusted maximum steer

angle to right side (CAN WAS) (P3195) ≤ 89

520241

2

3428

Maximum steer angle, right

Vehicle Geometry

3244

WAS interface

Peripherals Config

3193

Automatically adjusted

maximum steer angle to left

side (CAN WAS)

CAN WAS Calibration

Data

3195

Automatically adjusted

maximum steer angle to right

side (CAN WAS)

CAN WAS Calibration

Data

25

3086

Cylinder stroke volume

Hydraulic Config

If WAS interface (P3244) = ANALOG: Cylinder stroke volume

(P3086) ≤ 10000 Or

Automatically adjusted cylinder stroke volume (analogue WAS)

(P3221) ≤ 10000

520232

2

3221

Automatically adjusted

cylinder stroke volume

(analogue WAS)

Analog Sensor

Calibration Data

26

3086

Cylinder stroke volume

Hydraulic Config

If WAS interface (P3244) = CAN: Cylinder stroke volume

(P3086)≤ 10000 Or

Automatically adjusted cylinder stroke volume (CAN WAS)

(P3191) ≤ 10000

520232

2

3191

Automatically adjusted

cylinder stroke volume (CAN

WAS)

CAN WAS Calibration

Data

27

3297

PVED-CLS source address

SEHS Protocol Data

A warning shall be displayed when same source addresse is set

for Main and Safety controllers

17.2

ERROR CODES

J1939-73 DM1, DM2 and DM3 diagnostic protocol is supported.

The list of DTC is divided in 7 sections:

1.

I/O signals:

This sections lists all failures related to analogue and digital inputs & outputs

2.

CAN Messages:

This Section lists all failures related to CAN messages

3.

Safety Functions:

This Section lists all failures caused by Safety functions and externally triggered safe state

DTC’s

4.

Diagnostic functions:

This section lists all failures detected by diagnostic functions

5.

Internal Hardware:

This section lists all failures found on the internal PCB in PVED-CLS

6.

Software:

This section lists all failures detected inside the software

7.

Monitoring:

This section lists all failures detected by crosscheck input signal and calculation results on SPI

between main and Safety UC

Category

SPN

Signal Name

Failure mode

FMI

Severity

Possible root cause(s)

I/O Signals

520192

Analogue sensor connected to

AD1

Short circuit to GND

4 - Voltage below normal or short-

circuit to low source

Severe

1.

Wire connected to AD1 lost connection (open circuit).

2.

Wire connected to AD1 short circuit to GND.

Short circuit to VCC

3 - Voltage above normal or short-

circuit to high source

Severe

1.

Wire connected to AD1 short circuit to a source higher than 4.9V.

Too high deviation

25 - Signal crosscheck failed

Severe

1.

Wheel angle sensors are not calibrated properly.

2.

Sensor characteristics have changed.

3.

If two physical separated sensors are used, one of them has lost the

mechanical connection or has increased hysteresis

Summary of Contents for PVED-CLS

Page 6: ...6 Danfoss August 2018 AQ00000211 ENGINEERING TOMORROW ...

Page 71: ... Danfoss August 2018 AQ00000211 71 ENGINEERING TOMORROW Figure 29 ...

Page 127: ... Danfoss August 2018 AQ00000211 127 ENGINEERING TOMORROW ...

Page 147: ... Danfoss August 2018 AQ00000211 147 ENGINEERING TOMORROW ...

Page 182: ...182 Danfoss August 2018 AQ00000211 ENGINEERING TOMORROW ...