CR-MM-1-0-00

PS-28 Cruiser

PS-28N Cruiser

CHAPTER 15 – AIRPLANE REPAIRS

Date of issue: 2011-03-08

Revision No.: -

15 - 7

(f) Use at least two rivets on each side from the crack.

(g) At riveting follow Section 15.3.

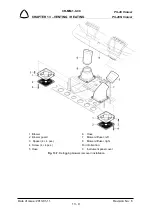

Fig. 15-2

: Scheme of angle repair

15.4.5

Skin repair

15.4.5.1

Stopping cracks and blinding small holes

Enlarging of small cracks can be stopped by drilling a hole with the drill bit of dia 3.2 mm

(

1/8 in

) at the utmost end of the crack. If enlarging continues, repeat the drilling. Support

the place of drilling with a wooden block at drilling thin skin and use the sharp drill bit so that

it will not drift and will not cause another damage to the skin. Check in the operation whether

the crack was successfully stopped.

At drilling the crack of the skin in the area of the flange, supporting stiffener etc., protect

these parts before drilling by supporting the drilled place by means of the thin steel band. If

the crack still enlarges after repeated drilling, cut out the affected area and repair the skin

by means of the patch - see next paragraph.

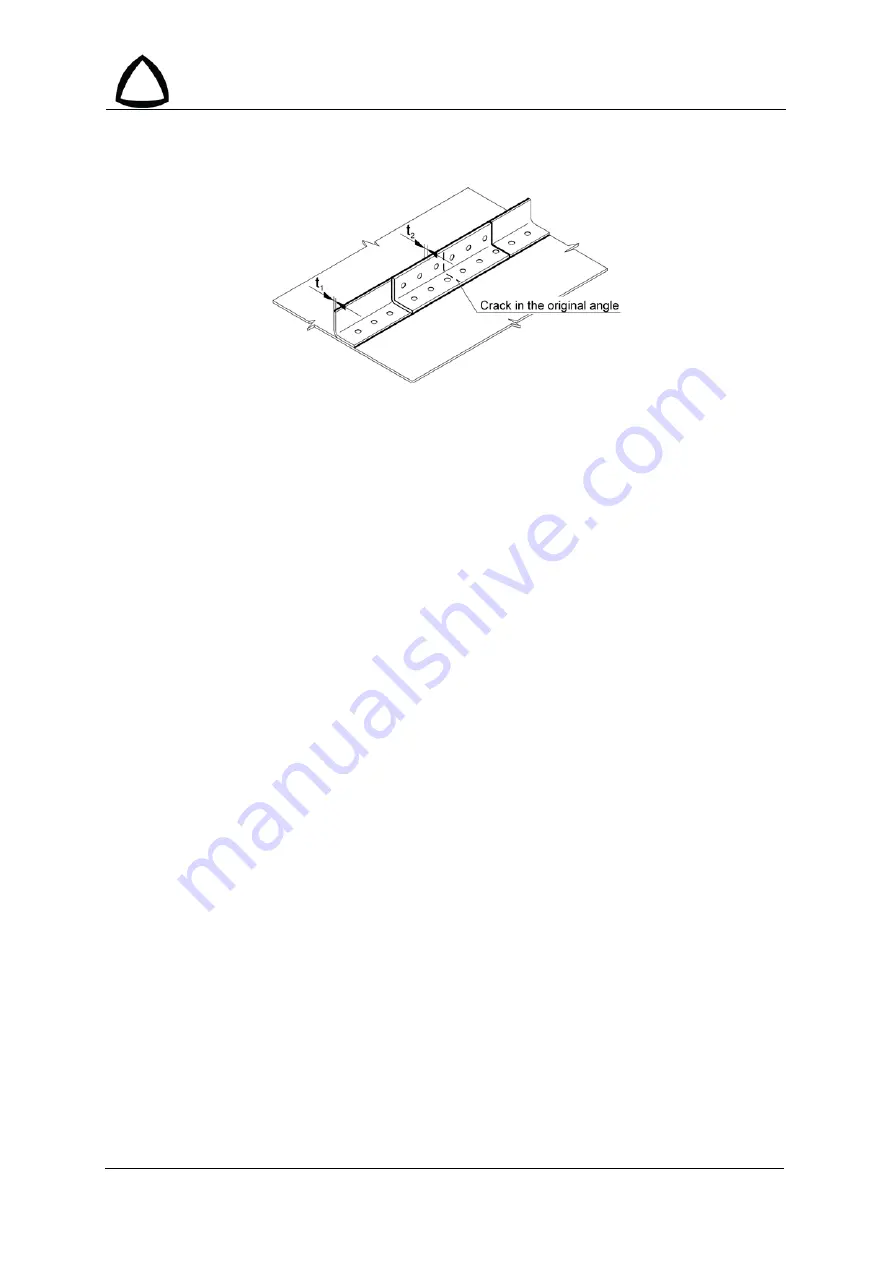

15.4.5.2

Repairing the skins with patches

CAUTION:

THE FOLLOWING PROCEDURE IS INTENDED FOR SKIN REPAIRS ONLY

WITH MAX. AREA OF THE PATCH UP TO 200 cm

2

(

31 sq in

) (AREA OF THE

CUT OUT SKIN). BEFORE RIVETING THE PATCH CHECK THE ADJACENT

PART OF THE INNER STRUCTURE IN THE DAMAGED AREA AND FIND

OUT WHETHER ITS REPAIR IS NEEDED. PLACE PATCHES ON THE

FUSELAGE SO, THAT THE LONGER PATCH SIDE LIES IN THE

LONGITUDINAL PLANE OF THE AIRPLANE (IN FLIGHT DIRECTION), SEE

FIG.15-3. PLACE PATCHES ON THE WING SO, THAT THE LONGER

PATCH SIDE LIES IN DIRECTION OF TRANSVERSAL AXIS OF THE

AIRPLANE (PARALLEL WITH THE WING LEADING EDGE), SEE FIG. 15-3.