CR-MM-1-0-00

PS-28 Cruiser

PS-28N Cruiser

CHAPTER 15 – AIRPLANE REPAIRS

Date of issue: 2011-03-08

Revision No.: -

15 - 5

in such a way that the rivets head overruns the area before riveting max. by

0.2 mm (

0.008 in

), the rivet head must not be under the surface level (sunk).

(c) Before applying the bonding sealant carefully clean the connected parts of impurities

and degrease contact surfaces by appropriate agent, e.g. industrial spirit.

NOTE:

For cleaning and degreasing use a clean paper towel or cloth. After wiping,

the towel or cloth must not show any contamination. For perfect degreasing

the whole surface, clean always smaller part of surface, after its perfect

cleaning continue on. Cleaning liquid always apply on the cloth only and wipe

it off from the surface before its evaporating.

(d) Apply bonding sealant on one of the surfaces, which should be sealed together. Apply

the adhesive directly from the packing by means of the extrusion gun, plastic spatula or

paintbrush in such a way that the layer of sealant is equally thick and integral, without

bubbles or uncovered areas. The optimum thickness of the applied coat is 0.25 mm

(

0.01 in

).

NOTE:

The surfaces that are to be connected must be dry and clean before

application of bonding sealant.

(e) After applying bonding sealant connect both parts together, fix them by clecos and rivet

them.

NOTE:

After proper riveting the continual bur of adhesive is created on the edge of

connected surfaces. If this bur is big, it is possible to wipe it off with the plastic

spatula and finally with cloth dipped in degreasing agent.

(f) After riveting, seal rivet heads, there, where are used pop rivets - see 15.6.2.2

15.4

Skin repairs

15.4.1

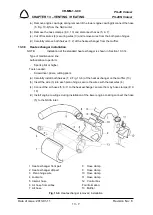

Removing damaged skins

In case that it is necessary to remove bigger part of the skin, ensure reliable support of the

structure. Appropriately support the damaged part of the fuselage monocoque or the wing

by supports located in the area of fuselage frames or wing ribs. The shape of supports must

correspond with the shape of supported place and must be supplemented by cushion (or

with other suitable material), so that airplane skin surface cannot be damaged. Remove

rivets according to Section 15.2.

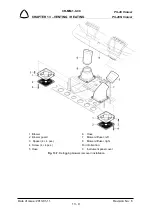

15.4.2

Division of damaging into groups

To determine way of repair, find out by inspection the scope of structural damage, also in

case of possible unriveting the skin.

Damage can be divided into the following groups:

(a) Little damage, which do not have to be repaired, such as local small impacts, scratches

in the skin not exceeding thickness of the zinc chromated layer, appearance defects of

paint coat etc.

(b) Damage, which can be eliminated by airplane operator. Methods of elimination are

describer further in the text.