Chapter 2

2-47

F-2-117

4) The machine rotates the transport belt. The original is moved over a specific distance after its trail edge has moved past the reversal sensor (S1), and is then

stopped.

F-2-118

5) The host machine starts printing operation.

F-2-119

6) When the host machine's scanner starts to move in reverse, the machine starts to rotate the transport belt and the delivery roller, thus moving the original to the

delivery assembly.

F-2-120

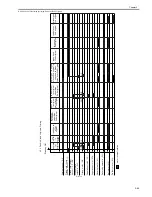

Sequence of Operation

F-2-121

2.7 Detecting Jams

2.7.1 Overview

0011-2392

The machine checks for jams using the following sensors. The CPU on the ADF controller PCB runs a check at such times as programmed in advance, and detects

the presence/absence of a jam in relation to the presence/absence of paper over a specific sensor.

Upon detection of a jam, the machine communicates the fact to the host machine, which in turn indicates the fact in service mode in the form of a code. A check

may also be made with reference to the indicator (LED2) of the machine's ADF control PCB.

Service Mode Screen of the Host Machine

Reversal sensor(S1)

Reversal sensor(S1)

Copy

Start key ON

Original placed in manual feeder

Belt motor (M2)

Delivery solenoid (M5)

Reversal solenoid

(SL4)

Manual feeder placement

sensor(PI 12)

Reversal sensor

(SL1)

Original delivery

sensor(PI 1)

Original placed in

manual feeder(PI 13)

pickup

discharge

move

original placed

0.4 sec (approx.)

Summary of Contents for DADF-Q1

Page 1: ...Aug 24 2007 Service Manual Feeder DADF Q1 ...

Page 2: ......

Page 6: ......

Page 11: ...Chapter 1 Specifications ...

Page 12: ......

Page 14: ......

Page 18: ......

Page 19: ...Chapter 2 Functions ...

Page 20: ......

Page 22: ......

Page 75: ...Chapter 3 Parts Replacement Procedure ...

Page 76: ......

Page 107: ...Chapter 4 Maintenance ...

Page 108: ......

Page 149: ...Chapter 5 Error Code ...

Page 150: ......

Page 152: ......

Page 154: ......

Page 155: ...Aug 24 2007 ...

Page 156: ......