Chapter 4

4-22

F-4-108

2) Mount the EEPROM removed in step 1) to the new ADF controller PCB.

MEMO:

The EEPROM on the new ADF controller PCB is not used yet.

3) Turn on the copier, and check to make sure that error code E420 is not in-

dicated.

4) If error code E420 is indicated, mount back the EERPOM once removed

from the new ADF controller PCB.

5) Perform the work under 1.2.3 "Adjusting the Sensors and the Delivery

Motor."

4.3.2.3 Adjusting the Sensors and the

0011-3501

Perform the adjustment if you have replaced any of the following parts:

- EEPROM (memory backup)

- Reversal sensor (S1)

- Pre-registration roller senor (S2)

- Post-registration roller sensor (S3)

- Separation paper sensor (S4)

- Skew paper sensor (S5)

- Original sensor (S6)

- Original trailing edge sensor (S7)

- Manual feed registration roller paper sensor (S9)

- Delivery motor (M5)

MEMO:

The delivery motor is adjusted by sending a reference signal to it, and the

speed of rotation at that time is measured by the delivery motor clock sensor

(PI11).

The result is used when generating the motor rotation speed control signal

(EJMPWM*).

Steps to Take

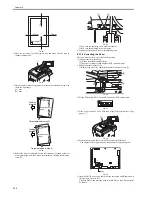

1) Open the DADF, and make a single A4 copy of a solid black original.

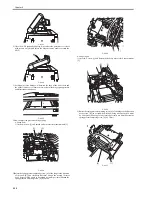

2) Remove the screw [1], and detach the ADF controller cover [2].

F-4-109

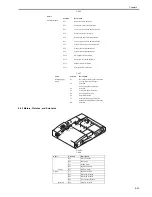

3) Set the DIP switch (SW1) on the ADF controller PCB as indicated.

F-4-110

4) Place the output obtained in step 1) in the original tray with the black side

facing down. Take care not to cover the original sensor (S6) when placing

the output.

F-4-111

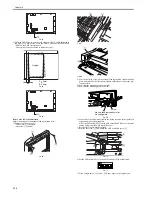

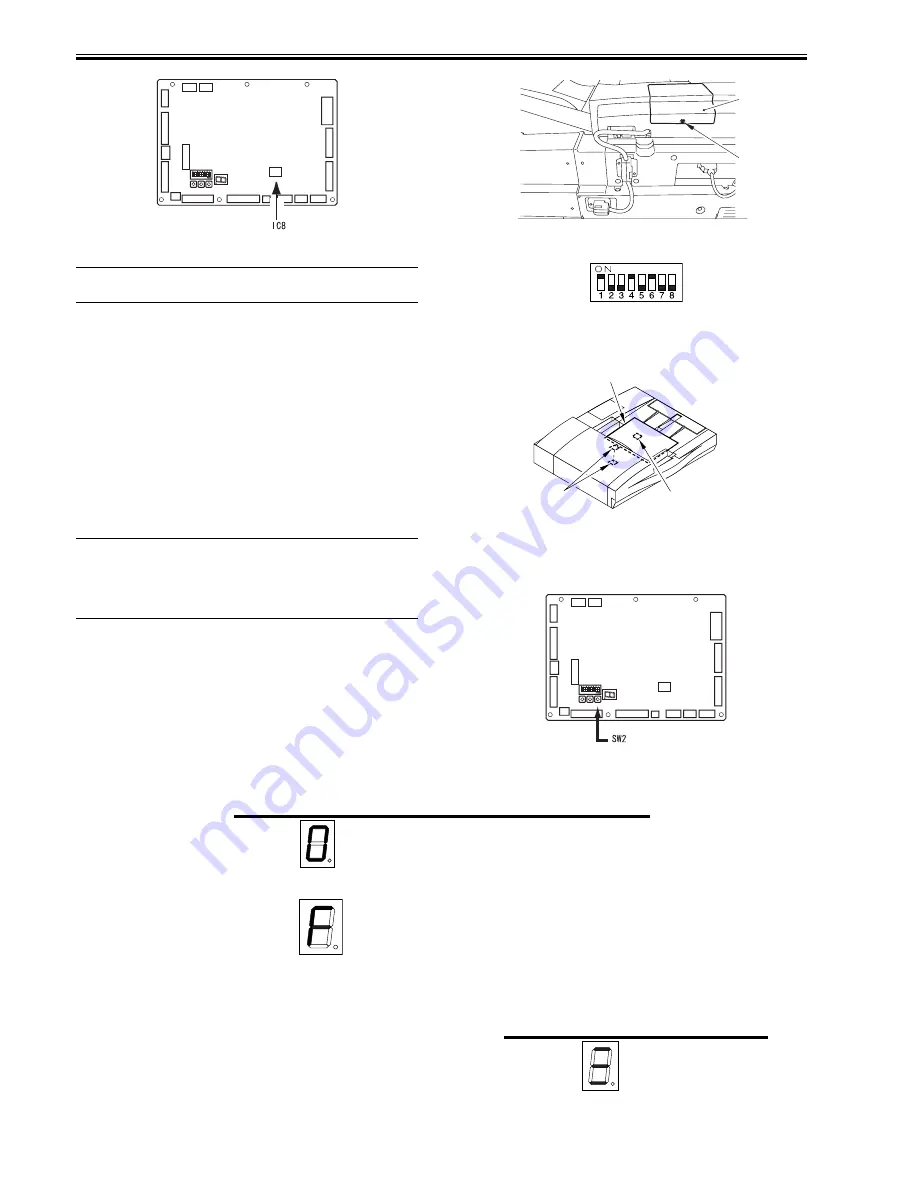

5) Press the push switch (SW2) on the ADF controller PCB.

- The LED will indicate the following in sequence, showing the result at

the end: 1, 2, 3, 4, 5, 6, 7, 8, 9, A.

F-4-112

T-4-10

6) At the end of the operation, press the push switch (SW2) on the ADF con-

troller PCB once again.

If the Result is NG

Check the condition of each of the sensors (S1 through S9), and replace the

sensor considered to be faulty.

The condition of a sensor is indicated in the following three levels:

T-4-11

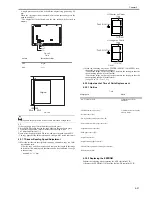

J1

J2

J5

J3

J6

J7

J8

J9

J10

J16

J15

J11

J14

IC8

J13

J12

J4

CB1

SW1

DSP1

SW4SW3SW2

[1]

[2]

Black side down

Original

sensor (S6)

Original trailing

edge paper sensor

(S7)

J1

J2

J5

J3

J6

J7

J8

J9

J10

J16

J15

J11

J14

IC8

J13

J12

J4

CB1

SW1

DSP1

SW4SW3SW2

Result

LED2 indication

Description

OK

(O)

All sensors (S1 through S9) are normal).

NG

(F)

Any of the sensors (S1 through S9) is faulty.

Condition

DSP1 indication

Check or replace

Good

No

Summary of Contents for DADF-Q1

Page 1: ...Aug 24 2007 Service Manual Feeder DADF Q1 ...

Page 2: ......

Page 6: ......

Page 11: ...Chapter 1 Specifications ...

Page 12: ......

Page 14: ......

Page 18: ......

Page 19: ...Chapter 2 Functions ...

Page 20: ......

Page 22: ......

Page 75: ...Chapter 3 Parts Replacement Procedure ...

Page 76: ......

Page 107: ...Chapter 4 Maintenance ...

Page 108: ......

Page 149: ...Chapter 5 Error Code ...

Page 150: ......

Page 152: ......

Page 154: ......

Page 155: ...Aug 24 2007 ...

Page 156: ......