Control Wiring 5-3

MN765

5.2 Analog Inputs

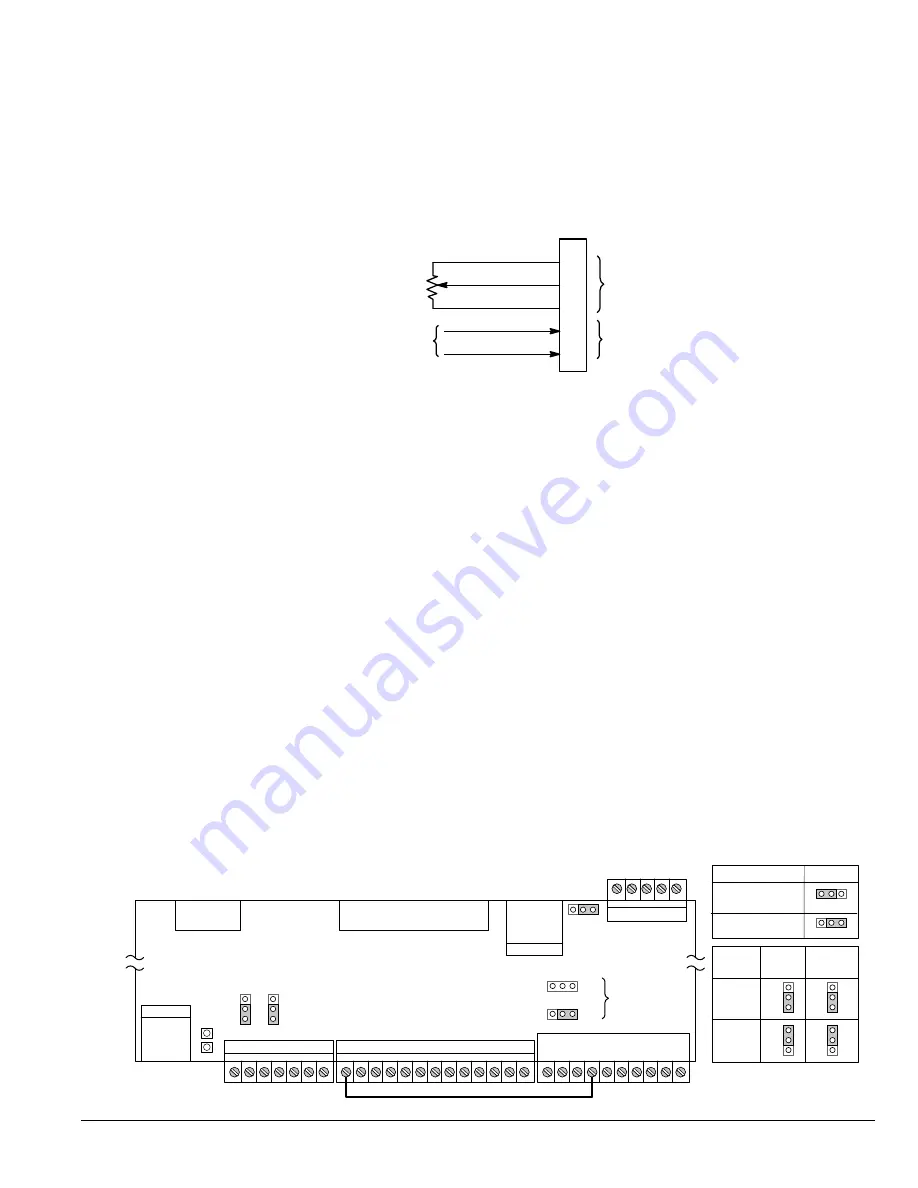

Two analog inputs are available: Analog Input 1 (J1-1 and J1-2) and Analog Input 2 (J1-4 and J1-5) as shown in Figure 5-2.

Either analog input may be selected in the Level 1 Input block, Command Source Parameter.

Figure 5-2 Analog Inputs

J1

Analog GND

Analog Input 1

Pot Reference

Analog Input +2

Analog Input -2

1

2

3

4

5

Analog Input 1

Analog Input 2

Command Pot or

0 - 10VDC

± 5VDC, ±10VDC,

0-20mA or 4-20mA Input

See recommended terminal tightening torques in Table A-2.

5.2.1 Analog Input 1 (Single Ended)

When using a potentiometer as the speed command, process feedback or setpoint source, the potentiometer should be

connected at Analog Input 1. When using Analog Input 1, the respective parameter must be set to “Analog Input 1”.

Note:

A potentiometer value of 5kΩ to 10kΩ, 0.5 watt may be used.

Parameter Selection

The single ended Analog Input 1 is typically used in one of three ways:

1. Speed or Torque command (Level 1 Input block, Command Source=Analog Input 1).

2. Process Feedback (Level 2 Process Control block, Process Feedback=Analog Input 1).

3. Setpoint Source (Level 2 Process Control block, Setpoint Source=Analog Input 1).

5.2.2 Analog Input 2 (Differential)

Analog Input 2 accepts a differential command ±5VDC, ±10VDC, 0-20 mA or 4-20 mA.

If pin J1-4 is positive with respect to pin 5 and P1408=±5V or ±10V, the motor will rotate in the forward direction.

If pin J1-4 is negative with respect to pin 5 and P1408=±5V or ±10V, the motor will rotate in the reverse direction. If forward

direction is not correct, change Level 2, Motor Data Reverse Rotation parameter P2415.

Analog Input 2 can be connected for single ended operation by connecting either of the differential terminals to common,

provided the common mode voltage range is not exceeded.

Analog Input 2 can be set for voltage or current mode operation. With JP1 as shown in Figure 5-3 , Voltage mode is

selected. If JP1 is connected to pins 2 and 3, current mode is selected.

The Level 1 Input Setup Parameter P1408 can be set to the full scale voltage or current range desired.

Note:

The common mode voltage can be measured with a voltmeter. Apply the maximum command voltage to Analog Input

2 (J1-4,5). Measure the AC and DC voltage across J1-1 to J1-4. Add the AC and DC values. Measure the AC and DC

voltage from J1-1 to J1-5. Add these AC and DC values. If either of these measurement totals exceeds a total of ±15

volts, then the common mode voltage range has been exceeded. To correct this condition, isolate the command

signal with a signal isolator, such as Baldor catalog number BC145.

Figure 5-3 Jumper Locations

Fault

USB

USB Port

J1

J2

J3

JP1

JP2

JP3

1

1

1

RS485

Keypad

Connector

Ribbon

Cable

Regen

Connector

Control

Circuit Board

JP6

JP5

P1

J7

J8

P2

P3

S G A B S

ENP

EPN

INP

DFT

Factory Settings

as shown

Note: Factory connection of

J2-8 (Enable) to J3-24.

24

8

See recommended tightening torques in Table A-2.

JP1

JP2

ANAIN2 ANAOUT1

Voltage

Current

1

1

1

1

Type

1

JP3

1

No Termination

120 ohm

Termination

RS485

Summary of Contents for VS1GV21-1B

Page 1: ...10 11 Installation Operating Manual MN765 VS1GV AC Closed Vector Control...

Page 12: ...2 2 General Information MN765...

Page 16: ...3 4 Installing the Drive MN765...

Page 78: ...6 16 Using the Keypad MN765...

Page 132: ...9 14 Troubleshooting MN765...

Page 172: ...A 16 Technical Specifications MN765...

Page 200: ...E 2 Remote Keypad Mounting Template MN765...

Page 201: ...Remote Keypad Mounting Template E 3 MN765...