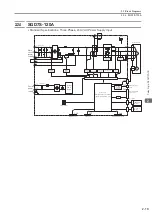

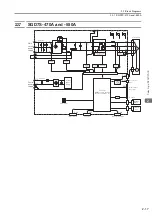

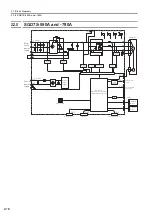

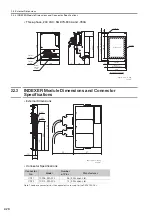

2.4 Examples of Standard Connections between SERVOPACKs and Peripheral Devices

2-27

2

Selecting a SER

VOP

ACK

2.4

Examples of Standard Connections between SERVOPACKs and Peripheral Devices

•

Rotary Servomotors

*1.

This example is for a SERVOPACK with a three-phase, 200-VAC power supply input. The pin layout of the main

circuit connector depends on the voltage.

*2.

External Regenerative Resistors are not provided by Yaskawa.

*3.

The power supply for the holding brake is not provided by Yaskawa. Select a power supply based on the hold-

ing brake specifications.

If you use a 24-V brake, install a separate power supply for the 24-VDC power supply from other power sup-

plies, such as the one for the I/O signals of the CN1 connector.

If the power supply is shared, the I/O signals may malfunction.

Servomotor

Main Circuit Cable

Encoder Cable

Battery Case

Holding brake

power supply unit

* 3

Magnetic Contactor

(Wires required for a Servomotor with a Brake)

External

Regenerative

Resistor

* 2

Noise Filter

Molded-case

circuit breaker

Magnetic Contactor

I/O Signal Cable

SERVOPACK

Rotary Servomotor

Direct Drive Servomotor

Power supply

Three-phase, 200 VAC

* 1

(Used for an absolute

encoder.)

Computer

Computer Cable

External

Regenerative

Resistor Cable

Control

Power

Supply Cable

Digital

Operator

Digital Operator cable

Analog Monitor Cable

Ground

cable

SERVOPACK

main circuit wires

Support

Software

Servomotor

Main Circuit Cable

Encoder Cable

Sequence I/O

signal cable

Host controller

Serial command

communications cable

When a Safety Function Is Not Used:

When a Safety Function Is Used:

Safety function device

Leave the enclosed JZSP-CVH05-E

Safety Jumper Connector attached.

Safety Function Device Cable

CN5

CN3

CN7

CN12

CN1

CN8

CN2

R S T

CN11