64

4.

For the Service Technician

4. For the Service Technician

4.1 Start-up and operating instructions

Windhager customer service or a customer service partner will commission the boiler and familiarize the

customer with the system operations and cleaning procedures. Commissioning and maintenance are part of the

guarantee requirements of the “Warranty conditions” – see section 1.4.

We recommend that you obtain a maintenance service contract.

4.2 Service and repair work

Service and repair may only be performed by appropriately qualified technicians.

Attention!

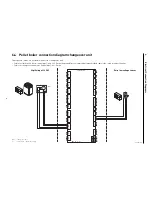

After the emergency shut-off switch trips, the boiler and accessories are not completely without

power! When replacing system components (pumps, mixing valves, etc.) prevent all power input (e.g.

by disconnecting both

power plugs

).

Please note:

Before opening a control panel for service or repairs, the device mains power plug on both boilers must be dis-

connected.

Fig. 160 Disconnect both power plugs

Devices power plug wood gasification boiler

Devices power plug pellet boiler

4.3 Checking and servicing the thermal process safeguard

(Please inform your customer)

Attention!

The function of the thermal process safeguard must be checked once a year by a technician and the

amount of limescale in the thermal safety device must be checked. If there is limescale in the ther-

mal safety device then it must always be removed.

– Press the red cap against the valve (Fig. 161) > Water must flow out into

the funnel.– Little outflow at funnel > Limescale in thermal safety de-

vice (pump limescale remove – e.g., formic acid – through the thermal

safety device).

– Thermal process safeguard dripping > Clean the seal on the piston and

valve seat. If the seal is damaged > Renew the piston.

Note:

There is no need to remove the fitting for this purpose!

Fig. 161 Thermal process safeguard,

Press the red cap against the valve

Содержание DuoWIN

Страница 15: ...15 2 For the Installer ...

Страница 69: ...69 5 Technical Data ...