4

1.

Important Initial Information for the Technician

1. Important Initial Information for the Technician

The DuoWIN hybrid boiler constitutes the LogWIN Klassik pellet ready wood gasification boiler and the BioWIN 2

pellet boiler with a shared InfoWINPLUS display and operating unit.

1.1 Safety precautions

This boiler and related accessories are state of the art and meet all applicable safety regulations. This boiler

and all accessories operate using 230 V AC electrical current. Improper installation or repair can result in a life-

threatening electric shock. Installation may only be performed by appropriately qualified technicians.

Caution symbols

Please take careful note of the following symbols in this installation manual and on the boiler.

Attention!

Ignoring the warnings identified can lead to

personal injury

.

Information!

Ignoring the warnings identified can lead to

malfunction of, or damage to the boiler or heating system

.

Note!

The blocks of highlighted text provide

information and tips

for operation.

1.2 Flue

A properly dimensioned flue is required for optimal functioning of the combustion system. Measurement of the

dimensions must follow EN 13384-1. See the technical data section for the values required for this calculation.

Please note that in the lower performance range, flue gases may be below 90°C. Hearths should therefore be

connected to thermally insulated flues meeting thermal transmittance coefficient Group I requirements according

to DIN 18160 T1 or other appropriate, officially approved moisture-resistant exhaust systems.

The flue gas system must display at least the following classification:

Temperature class:

T400 = nominal operating temperature 400 °C

Soot fire resistance class:

G = flue gas system with soot fire resistance

Corrosion resistance class:

2 = suitable for unprocessed wood fuels

We recommend fitting an energy-saving intake regulator for problem-free operation. This will largely prevent

moisture in the flue, and losses resulting from down-time will be reduced (draught interruptions). If you have a

feed pressure (flue draught) of more than 0.20 mbar, the energy-saving intake regulator must be fitted.

According to TRVB H118, a deflagration flap (combi energy-saving intake regulator with explosion flap EEX) must

be fitted in the connecting piece (exhaust pipe) or in the flue inside the boiler room.

Please observe the following sections:

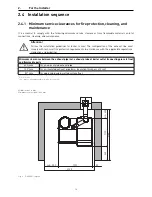

2.4.1

Minimum service clearances for fire protection, cleaning, and maintenance

2.4.43 Exhaust pipe installation

Information!

Frequently, overhauling existing systems involves over-sized flue cross-sections or flues not

designed for low-temperature operation. We recommend an evaluation by the local building

inspector before installing the boiler system. In this way, appropriate modifications can be made to

the flue before system installation (see technical data for flue calculation values).

Содержание DuoWIN

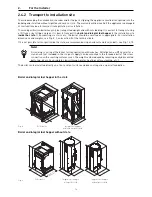

Страница 15: ...15 2 For the Installer ...

Страница 69: ...69 5 Technical Data ...