1-43

Figure A

Figure B

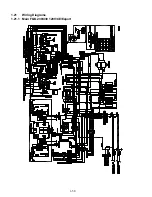

Figure C

If oil is surrounding the heater, the oil will

prevent the heater from ever reaching its

setpoint. Once oil is removed during

filtration the heater reaches setpoint and

cycles a thermostat every four seconds.

Since the cycle is only four seconds, the

seven second delay is not made and the

gas valve won’t open.

The 120VAC (220-240VAC on Intl.

units) is on T1 and T2 in the control box.

It is switched with 12 volts traveling in

from pin 5 of J3 and out to pins 5 and 7 on

AIF J2 and back in on pin 8 from AIF J2

(DV) or pin 6 from AIF J2 (FV) across the

relay coil.

Figure 26 Figure 27

1.17.5.1 Oil Level Sensor Troubleshooting

Typical Sensor Related Failures

- Low temp but no call for heat (heat light)

-Intermittent IS VAT FULL? displays are primarily due to

dirty OIB sensors or loose grounds. Ensure that the OIB

sensors are clean as shown in Figure A.

This is usually due to a caramelized oil buildup on

the sensor. Clean the oil level sensor with a

scratch pad and power cycle the controller.

Check grounds from the OIB relay and 7 second

timer board delay. When grounded to the stud on

the interface board they have a tendency to loosen.

They should NOT be grounded to interface board

studs as shown in Figure B. If so they should be

moved and be tightly grounded to stud in rear of

the fryer as shown in Figure C.

- Stuck in melt cycle with no call for heat

- Filter error (IS VAT FULL?) with oil in the filter pan (no

oil in the vat)

If the controller doesn’t exit melt cycle or continues to

display low temp and does not heat, and gas supply, gas

valve, etc. have been checked and no heat lamp illuminates because no call for heat is initiated, then follow

these steps:

- Check (see diagram next page)

- Power to oil sensor (from oil level sensor relay in component box). Check pin 5 on AIF J2 (DV) or

pin 7 on AIF J2 (FV) for 12VDC from interface board.

- Power to heater/relay coil on relay board. Check voltage to the coil between pins 8 and 1 to ensure

that 120VAC (220-240VAC on Intl. units) is present with oil in the vat. If the vat is empty, the

power will cycle 4 seconds on, 4 seconds off.

- Check between pin 3 and 2 on the relay board reads 5VDC for air and 0VDC for oil. A common

message for a shorted harness or issue is “IS DRAIN CLEAR?” with oil in the filter pan.

- Check ground on pin 2 on relay board to stud for a secure ground.

- Check AIF communication harness. Interrupted communication will prevent the fryer from heating.

- If the oil level sensor is cycling 4 sec. on/off and oil is surrounding the sensor, the sensor may have

a carbon build up that is self insulating the sensor. Use a scratch pad to remove carbon build up.

Содержание Frymaster FilterQuick 2FQG30U

Страница 8: ...1 3 ...

Страница 41: ...1 36 1 16 2 Bulk Wiring ...

Страница 56: ...1 51 1 18 6 Clogged Drain Failed Oil Sensor Error Flowchart ...

Страница 57: ...1 52 1 18 7 Menu Trees 1 18 7 1 FilterQuick Controller Setup Menu Tree ...

Страница 58: ...1 53 1 18 7 2 FilterQuick Filter and Info Mode Menu Tree ...

Страница 62: ...1 57 1 20 Principal Wiring Connections ...

Страница 63: ...1 58 1 21 Wiring Diagrams 1 21 1 Main FQG 230 430 120V CE Export ...

Страница 64: ...1 59 1 21 2 Main FQG 230 430 Australia ...

Страница 65: ...1 60 1 21 3 Main FQG 230 430 120V CE Export with Solid Shortening ...

Страница 66: ...1 61 1 21 4 Main FQG 230 430 Australia with Solid Shortening ...

Страница 67: ...1 62 1 21 5 Main FQG 330 530 120V CE Export ...

Страница 68: ...1 63 1 21 6 Main FQG 330 530 Australia ...

Страница 69: ...1 64 1 21 7 Main FQG 330 530 120V CE Export with Solid Shortening ...

Страница 70: ...1 65 1 21 8 Main FQG 330 530 Australia with Solid Shortening ...

Страница 71: ...1 66 1 21 9 Transformer Filter Box 430 530 ...

Страница 72: ...1 67 1 22 Simplified Wiring Diagrams 1 22 1 FilterQuick FQG30 Series Simplified Wiring with Push Pull Handles ...

Страница 73: ...1 68 1 22 2 FilterQuick FQG30 Series Simplified Wiring with Push Buttons ...

Страница 74: ...1 69 1 22 3 FilterQuick FQG30 Series Data Network Flowchart ...

Страница 76: ...1 71 1 24 Shortening Melting Unit Wiring Diagram ...

Страница 77: ...1 72 1 25 Modular Basket Lift Wiring Diagram 100 120V 1 2 4 3 5 6 12 7 8050518E ...

Страница 79: ...1 74 1 27 Basket Lift Interface Harness ...