1-45

Problem

Probable Causes

Corrective Action

FILTER

and

CLEAN

AND FILTER

won’t

start.

Temperature too low.

Ensure fryer is at setpoint before starting these

functions.

Controller displays

filter busy

or

WAIT FOR FILTER

.

A.

Another filtration cycle is still in

process.

B.

Controller error.

A.

Wait until the previous filtration cycle ends

to start another filtration cycle or until the

MIB board has reset. This may take up to

one minute.

B.

If message is still displayed with no activity,

ensure the filter pan is empty and remove

and restore

ALL

power to the fryer.

Controller display s

IS

DRAIN CLEAR?

Clogged drain or Oil Level Sensor is

malfunctioning.

The oil level sensor detects that oil is not

draining possibly due to clogged drain. Ensure

drain is not clogged. If drain is not clogged, see

oil level sensor troubleshooting on page 1-51.

Controller displays

OIL

SENSOR FAIL

Oil level sensor is not functioning properly.

Check the oil level sensor and ensure that it is

working properly.

Controller displays

SERVICE

REQUIRED

followed

by the error

.

An error has occurred.

Press YES to silence alarm. The error is

displayed three times. See list of issues in

section 1.17.5. Fix issue. The controller

displays

SYSTEM ERROR FIXED?

YES/NO.

Press YES and follow prompts.

Pressing NO will allow the fryer to cook in

most cases, but error will be redisplayed every

15 minutes.

Controller display is in

wrong temperature

scale (Fahrenheit or

Celsius).

Incorrect display option programmed.

See section 1.18.2 on page 1-47 to change

temperature scale.

Controller displays

CHANGE FILTER

PAPER

.

Filter error has occurred, filter paper

clogged, 24 hour filter pad change prompt

has occurred or change filter paper was

ignored on a prior prompt.

Change the filter paper and ensure the filter pan

has been removed from the fryer for a minimum

of

30

seconds.

Do

NOT

ignore

CHANGE FILTER

PAPER

prompts.

Controller displays

hot-hi-1

.

Frypot temperature is more than 410ºF

(210ºC) or, in CE countries, 395ºF

(202ºC).

This indicates that the vat temperature has

exceeded certain parameters and has

discontinued heating. It is also displayed

during a high limit test.

Controller displays

HI-

LIMIT.

Controller in high-limit test mode.

This is displayed only during a test of the high-

limit circuit and indicates that the high-limit

has opened properly.

Controller displays

INSERT pan

.

A.

Filter pan is not fully inserted into

fryer.

B.

Missing filter pan magnet.

C.

Defective filter pan switch.

A.

Pull filter pan out and fully reinsert into

fryer.

B.

Ensure the filter pan magnet is in place and

if missing replace.

C.

If the filter pan magnet is fully against the

switch and controller continues to display

INSERT pan

, switch is possibly

defective.

Содержание Frymaster FilterQuick 2FQG30U

Страница 8: ...1 3 ...

Страница 41: ...1 36 1 16 2 Bulk Wiring ...

Страница 56: ...1 51 1 18 6 Clogged Drain Failed Oil Sensor Error Flowchart ...

Страница 57: ...1 52 1 18 7 Menu Trees 1 18 7 1 FilterQuick Controller Setup Menu Tree ...

Страница 58: ...1 53 1 18 7 2 FilterQuick Filter and Info Mode Menu Tree ...

Страница 62: ...1 57 1 20 Principal Wiring Connections ...

Страница 63: ...1 58 1 21 Wiring Diagrams 1 21 1 Main FQG 230 430 120V CE Export ...

Страница 64: ...1 59 1 21 2 Main FQG 230 430 Australia ...

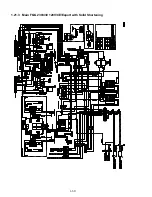

Страница 65: ...1 60 1 21 3 Main FQG 230 430 120V CE Export with Solid Shortening ...

Страница 66: ...1 61 1 21 4 Main FQG 230 430 Australia with Solid Shortening ...

Страница 67: ...1 62 1 21 5 Main FQG 330 530 120V CE Export ...

Страница 68: ...1 63 1 21 6 Main FQG 330 530 Australia ...

Страница 69: ...1 64 1 21 7 Main FQG 330 530 120V CE Export with Solid Shortening ...

Страница 70: ...1 65 1 21 8 Main FQG 330 530 Australia with Solid Shortening ...

Страница 71: ...1 66 1 21 9 Transformer Filter Box 430 530 ...

Страница 72: ...1 67 1 22 Simplified Wiring Diagrams 1 22 1 FilterQuick FQG30 Series Simplified Wiring with Push Pull Handles ...

Страница 73: ...1 68 1 22 2 FilterQuick FQG30 Series Simplified Wiring with Push Buttons ...

Страница 74: ...1 69 1 22 3 FilterQuick FQG30 Series Data Network Flowchart ...

Страница 76: ...1 71 1 24 Shortening Melting Unit Wiring Diagram ...

Страница 77: ...1 72 1 25 Modular Basket Lift Wiring Diagram 100 120V 1 2 4 3 5 6 12 7 8050518E ...

Страница 79: ...1 74 1 27 Basket Lift Interface Harness ...