1-32

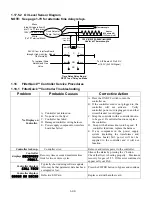

Problem

Probable Causes

Corrective Action

MIB board alternating

“

E”

and “vat number

and side

”.

Network error on the CAN bus

communication.

A.

Ensure the CAN bus system is terminated at

BOTH

ENDS

(on the FilterQuick™

controller connector J6 and on the ATO

board connector J10) with a resistor

equipped 6-pin connector.

B.

With the controller OFF, press the

temperature button and ensure the AIF

version appears. If not, the 24V to the AIF

boards may be missing. Ensure all 6-pin

CAN connectors are tight between the

FilterQuick™ controller (J6 and J7), MIB

(J1 and J2), AIF (J4 and J5) and ATO (J10)

boards.

C.

With the controller OFF, press the

temperature button and ensure the ATO

version appears. If not, check the CAN wire

harness between the AIF board J4 or J5 and

the ATO board J9 or J10. The ATO fuse on

the right side of the ATO box may be loose

or blown; the 110V to the ATO transformer

may be missing or bad. The J4/J5 connector

may be loose.

D.

Check to see if MIB has 24V on pins 5 and

6 of J2. Check to see if 24V is present on

pins 5 and 6 of wire harness plugging into

J4 or J5 of the first AIF board. If 24V

missing, check the pins. Replace the

harness if necessary.

E.

Check continuity between each color wire

on the CAN connectors into J7 on the far

right controller and J10 on back of the ATO

board (black to black, white to white, and

red to red), and ensure there is no continuity

between different color wires (black to red,

red to white, and white to black).

F.

Ensure black controller locator wires are

connected from ground to correct pin

position (see drawing 8051978 page 1-65).

G.

Ensure all boards have the corner ground

wire attached and tightened.

H.

The locator pin in J2 of the AIF board is

either loose or in the incorrect position. See

the charts on page 1-41 of this manual for

proper pin position.

I.

Bad MIB and/or AIF board.

J.

Broken resistor lead. Unwrap the resistor

leads and check ends.

Содержание Frymaster FilterQuick 2FQG30U

Страница 8: ...1 3 ...

Страница 41: ...1 36 1 16 2 Bulk Wiring ...

Страница 56: ...1 51 1 18 6 Clogged Drain Failed Oil Sensor Error Flowchart ...

Страница 57: ...1 52 1 18 7 Menu Trees 1 18 7 1 FilterQuick Controller Setup Menu Tree ...

Страница 58: ...1 53 1 18 7 2 FilterQuick Filter and Info Mode Menu Tree ...

Страница 62: ...1 57 1 20 Principal Wiring Connections ...

Страница 63: ...1 58 1 21 Wiring Diagrams 1 21 1 Main FQG 230 430 120V CE Export ...

Страница 64: ...1 59 1 21 2 Main FQG 230 430 Australia ...

Страница 65: ...1 60 1 21 3 Main FQG 230 430 120V CE Export with Solid Shortening ...

Страница 66: ...1 61 1 21 4 Main FQG 230 430 Australia with Solid Shortening ...

Страница 67: ...1 62 1 21 5 Main FQG 330 530 120V CE Export ...

Страница 68: ...1 63 1 21 6 Main FQG 330 530 Australia ...

Страница 69: ...1 64 1 21 7 Main FQG 330 530 120V CE Export with Solid Shortening ...

Страница 70: ...1 65 1 21 8 Main FQG 330 530 Australia with Solid Shortening ...

Страница 71: ...1 66 1 21 9 Transformer Filter Box 430 530 ...

Страница 72: ...1 67 1 22 Simplified Wiring Diagrams 1 22 1 FilterQuick FQG30 Series Simplified Wiring with Push Pull Handles ...

Страница 73: ...1 68 1 22 2 FilterQuick FQG30 Series Simplified Wiring with Push Buttons ...

Страница 74: ...1 69 1 22 3 FilterQuick FQG30 Series Data Network Flowchart ...

Страница 76: ...1 71 1 24 Shortening Melting Unit Wiring Diagram ...

Страница 77: ...1 72 1 25 Modular Basket Lift Wiring Diagram 100 120V 1 2 4 3 5 6 12 7 8050518E ...

Страница 79: ...1 74 1 27 Basket Lift Interface Harness ...