EUROBLOC

SERVICE MANUAL FOR HOIST

29/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

Component

In

te

rv

a

l

Inspection and maintenance task

Interval is SWP% reduction or calendar months

See further instructions

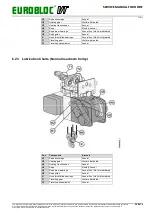

Contactors

Control

warning

12

Check that all the movements are operational in the hoist, in the

trolley and in the bridge.

Check visually that the contactors are clean and there are no visible

damages.

Contactors

Condition

monitoring unit

warning “Control"

When the condition monitoring unit indicates the “Control” warning, one of

the start counters 2-7 (ST up), 2-8 (ST down) or 2-9 (ST fast), has

reached the set design limit (the default value is 640,000 operations)

which is defined with parameter 6-19 (Max Control) that calculates the life-

time of the contactors.

When the design limit has been reached, replace the contactors (Up,

Down, Slow, Fast and Brake Contactors). If a brake contactor contains an

auxiliary contact block or a time delay auxiliary contact block, replace that

part as well.

After the replacement, calculate a new value for parameter 6-19. See

instructions in chapter “Contactors”.

If the condition monitoring unit is not used with the hoist, replace the

contactors after six years of operation according to the designed duty

cycle.

Over-current

protectors

10%

12

Check the adjustment of the over-current protectors.

Fuses

10%

12

Inspect visually that the fuse holder and the fuses are clean and

there are no visible damages.

Check the correct amperage rating.

Braking resistors

(with some

frequency

converter models)

10%

12

Clean all dust or dirt from the braking resistors.

Hoisting

frequency

converter

10%

12

Check that wires are securely fastened.

Check fault code records.

Inspect the operation and cleanliness of the cooling fan.

See further instructions in the

equipment-specific “Service Manual

for Frequency Control System”

Traveling

frequency

converter

10%

12

Check that wires are securely fastened.

Check fault code records.

Inspect the operation and cleanliness of the cooling fan.

See further instructions in the

equipment-specific “Service Manual

for Frequency Control System”

Frequency

controller

10%

12

Check fault code records.

Verify that the frequency converter fan is working.

Check that the frequency drive is clean from dust or dirt.

See further instructions in the

equipment-specific “Service Manual

for Frequency Control System”.

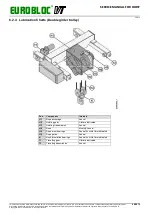

VARIATOR LM /

VARIATOR LA2

Condition

monitoring unit

warning “Control”

When the condition monitoring unit indicates the “Control” warning, the

design limit (the default value is 640,000 operations) has been reached.

Replace the brake timer block, the brake contactor as well as the brake

control PC board that contains the brake relay (in VARIATOR LM /

VARIATOR LA2 frequency converters, replace the B board).

Radio receiver

10%

12

Check that the radio receiver is working normally.

Motors and gears

Component

In

te

rv

a

l

Inspection and maintenance task

Interval is SWP% reduction or calendar months

See further instructions

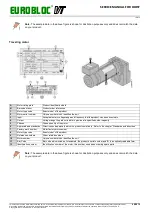

Hoisting motor

10%

12

Inspect for any unusual noise or vibration.

Drive and check that the hoisting motor operates properly when loaded.

Verify that the cooling fan is working properly.

Clean the cooling ribs surface from dust and dirt.

Check that all motor fastenings are tight and the motor is properly on

its position.

If the bolts are loose, tighten them to the proper torque.

Hoisting motor

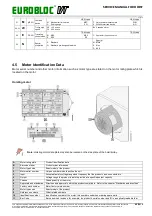

Maintenance of hoisting motor