EUROBLOC

SERVICE MANUAL FOR HOIST

109/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

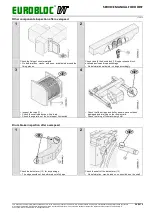

3

4

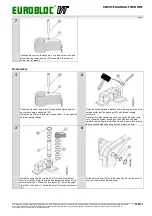

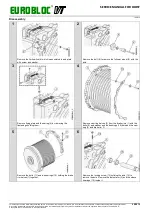

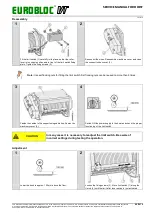

Adjust the cam wheel (2) so that when the follower roll (5) is

on the highest point of the cam wheel (2) there is a clearance

of 3 mm (0.12 ”) between the head of the detent arm (3) and

the tooth of the brake rim (13). If the cam wheel (2) is

replaced, position the cam wheel (2) by turning it until the

distance between the brake rim teeth (13) and the cam ring

wave peak is 36 mm.

Adjust the gap between the limit switch (6) and the roll (5) to

0.5 mm (0.02”). Make this adjustment when the follower roll

(5) is on the highest level of the cam wheel (2).

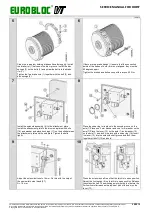

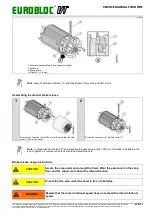

5

6

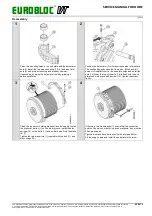

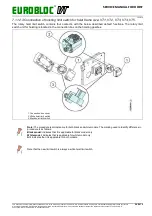

Adjust the length M of the helical spring (4) to the value

recorded on the drum brake report that is included in the

delivered hoist documentation. The follower roll (5) must be at

the highest point on the cam wheel when the length of the

spring is measured. Be aware that the spring must not be

damaged. If damaged, replace the spring. Verify the spring

type from the Q drum brake report.

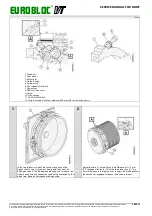

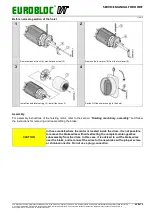

Verify that the brake rim (1) screws are loose allowing the

brake rims to slide freely on the drum during the following test.

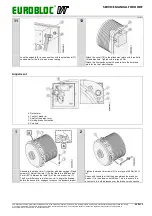

Test that the overspeed drum brake does not actuate when

lowering the nominal load with full speed. If the drum brake

activates, increase the M dimension to increase the follower

roll (5) tension on the cam wheel (2) preventing premature

drum braking action. Before repeating the test, verify that all

rim and cam wheel (2) positioning marks are correct according

to steps 3, 4 and 5.

7

8