EUROBLOC

SERVICE MANUAL FOR HOIST

203/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

Insert the shaft (1) through the bearing in the wheels. Mount

the rest of the shaft set (1) and lock shaft with snap rings.

Fix the end plate (6) and tighten the bolts according to

chapter “Recommended tightening torque”. Attach the

traveling machinery to the spline of driven wheel. Tighten the

screws of the machinery to a correct torque.

5

Connect the power supply plug to the motor and switch ON

the power supply to the hoist.

7.3.6.5 Maintenance of top running (double girder) trolley wheels

CAUTION

Asymmetrical wear may indicate misalignment on wheels. If the wheels are

asymmetrically worn, measure the wheel alignment. Readjust if possible or

change the parts if necessary.

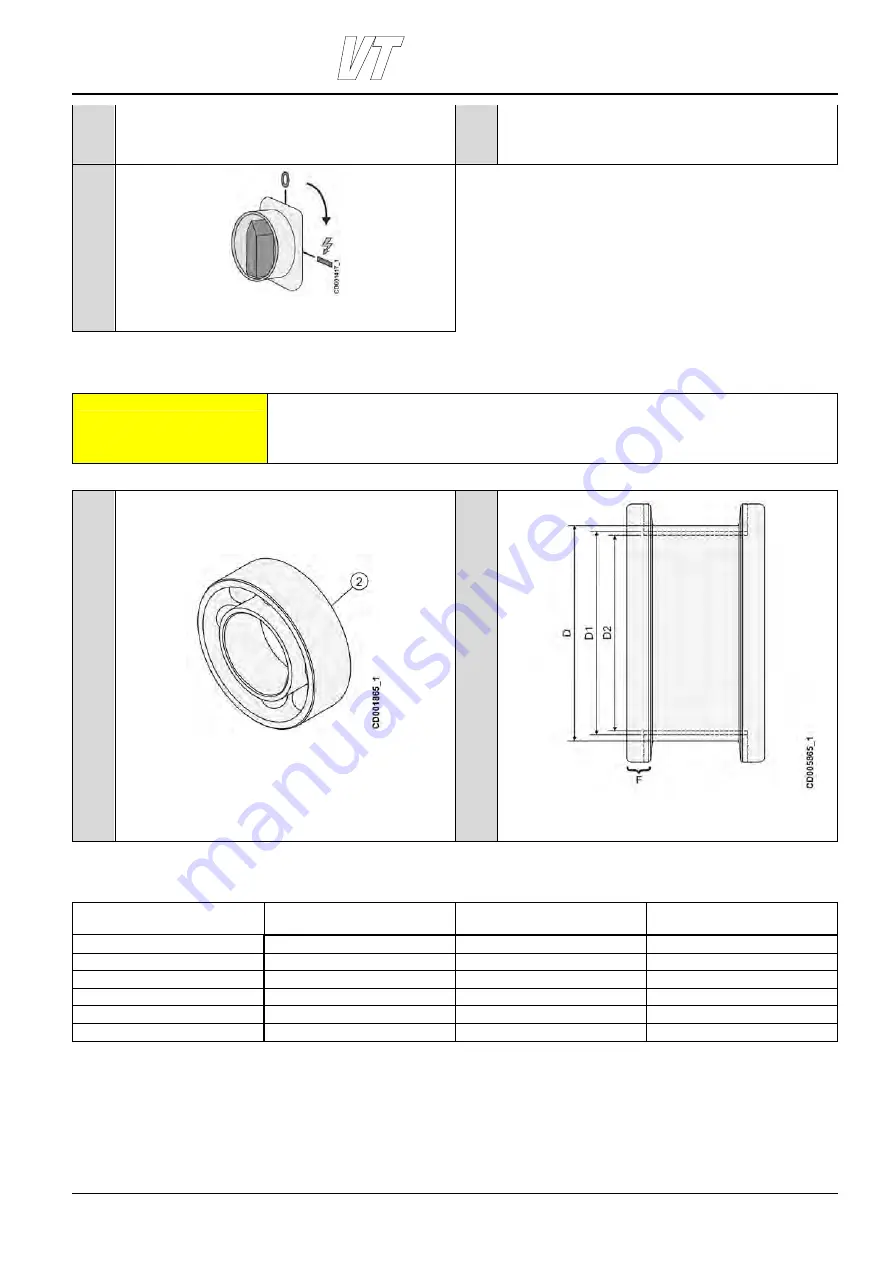

1

2

Check the condition of the wheel bearings (2) for wear or

any other damage. Replace if necessary.

Inspect visually the condition of trolley wheels. Change the

trolley wheels if they are worn more than the wear limits

given in the following table.

7.3.6.6 Wearing limits for top running trolley wheels

Wheel nominal diameter

D [mm]

Replace limit

D1 [mm]

Worn out limit

D2 [mm]

Min. thickness of the flange

F [mm]

90

87

84

6

100

97

94

7

110

107

104

8

140

135

130

8

200

195

190

11

250

245

240

11