EUROBLOC

SERVICE MANUAL FOR HOIST

183/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

3

4

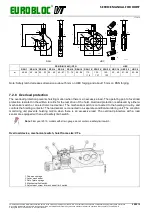

Load bearing structure

Check the load bearing structure (such as a load beam, the

end carriage housing). Replace the structure if deformations,

cracks, or broken welding seams are found.

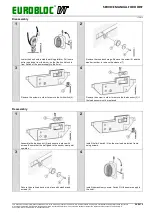

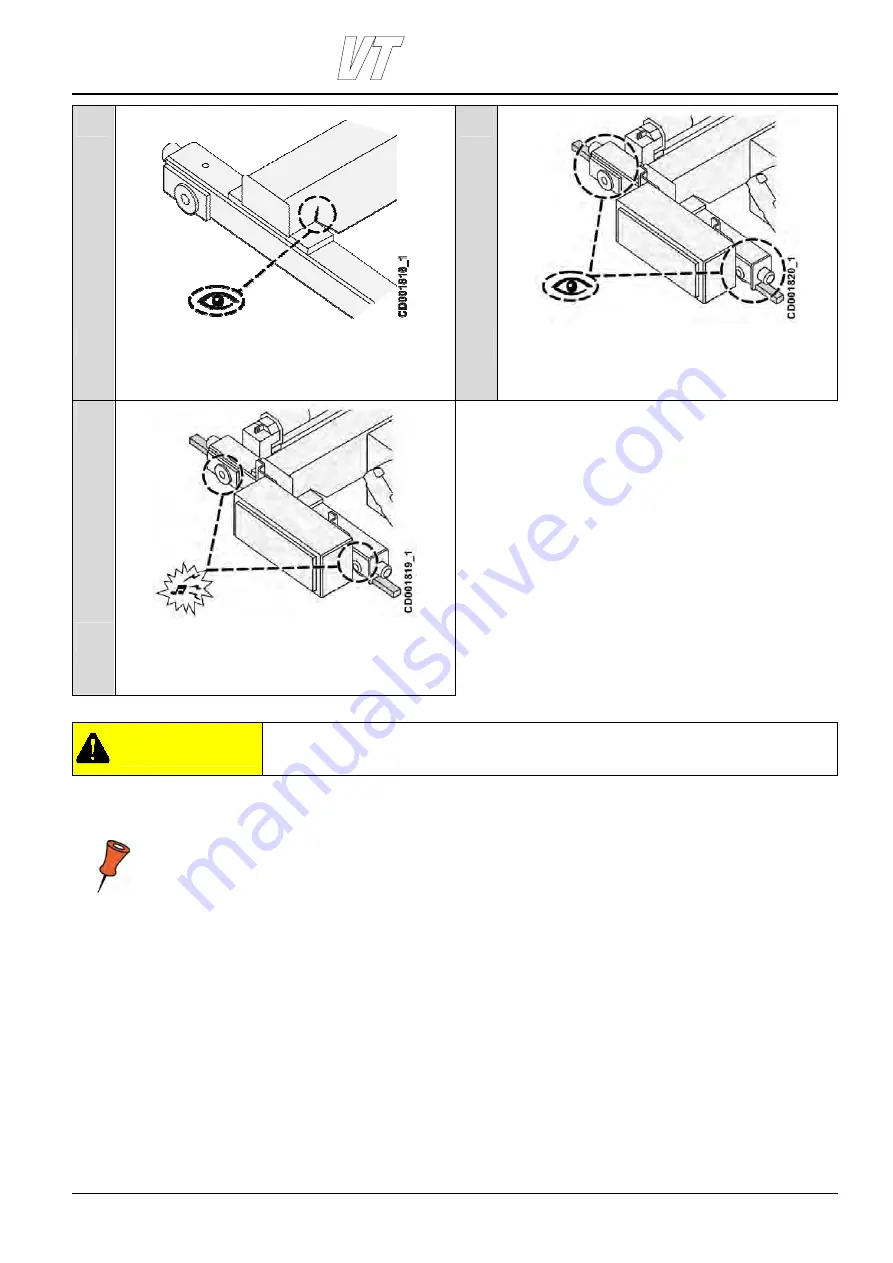

Trolley wheels

• Check that the wheels are correctly aligned.

• If an overspeed situation occurs, check that the trolley

wheels have not been damaged and that the trolley is

properly on the rails.

5

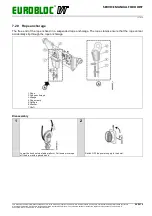

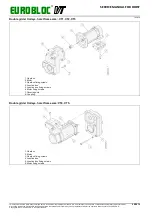

Trolley (alignment)

• If the traveling motion produces loud noise or strong

vibration, the trolley is probably incorrectly installed on the

track. Check that the trolley is properly mounted on the

track.

CAUTION

Do not use the hoist before you have identified and eliminated the cause of

excessive noise or vibration.

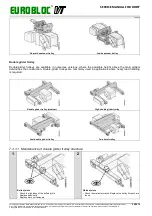

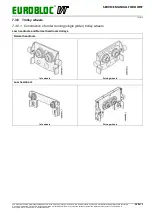

7.3.1.2 Maintenance of single girder trolley structure

Note: If the trolley is reassembled, the track width of the trolley must be properly adjusted.