EUROBLOC

SERVICE MANUAL FOR HOIST

91/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

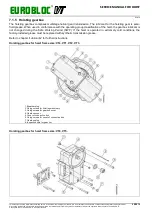

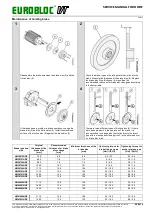

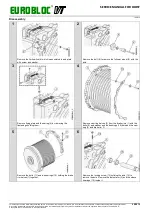

Limits for the wear of the brake splines on motor shaft

Motor

MF10

MF11

MF13

Module [mm]

1.25

1.25

1.25

Number of teeth

18

26

26

New Wn max [mm]

13.48

17.35

17.35

New Wn min [mm]

13.46

17.32

17.32

Change limit in GO Wn [mm]

13.4

17.2

17.2

Final rejection limit Wn [mm]

13.3

17.1

17.1

Number of teeth in measurement Wn

4

5

5

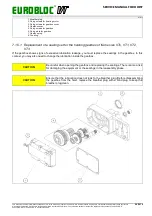

Limits for the wear of the coupling splines on motor and gear shaft

Motor

MF10

MF11

MF13

MF13

Module [mm]

1.0

1.5

1.5

2.0

Number of teeth

23

18

21

18

New Wn max [mm]

7.66

6.98

11.47

15.23

New Wn min [mm]

7.62

6.94

11.43

15.19

Change limit in GO Wn [mm]

7.5

6.7

11.2

15.0

Final rejection limit Wn [mm]

7.4

6.5

11.0

14.8

Number of teeth in measurement Wn

3

2

3

3

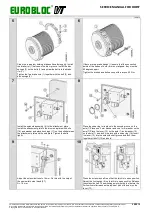

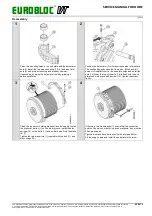

After the replacement, reset the hoisting brake SWP value by setting parameter 7-24 (Br Count) to zero (0).”

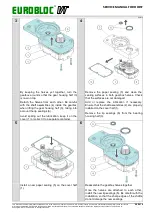

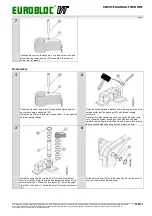

Disassembly

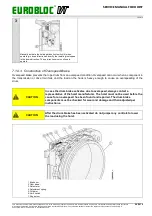

WARNING

Lock the rope drum to prevent it from rotating when hoisting brake is

detached. The weight of falling rope can rotate the unlocked drum and cause

hazardous situation.

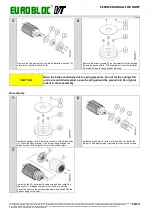

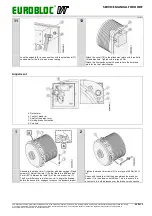

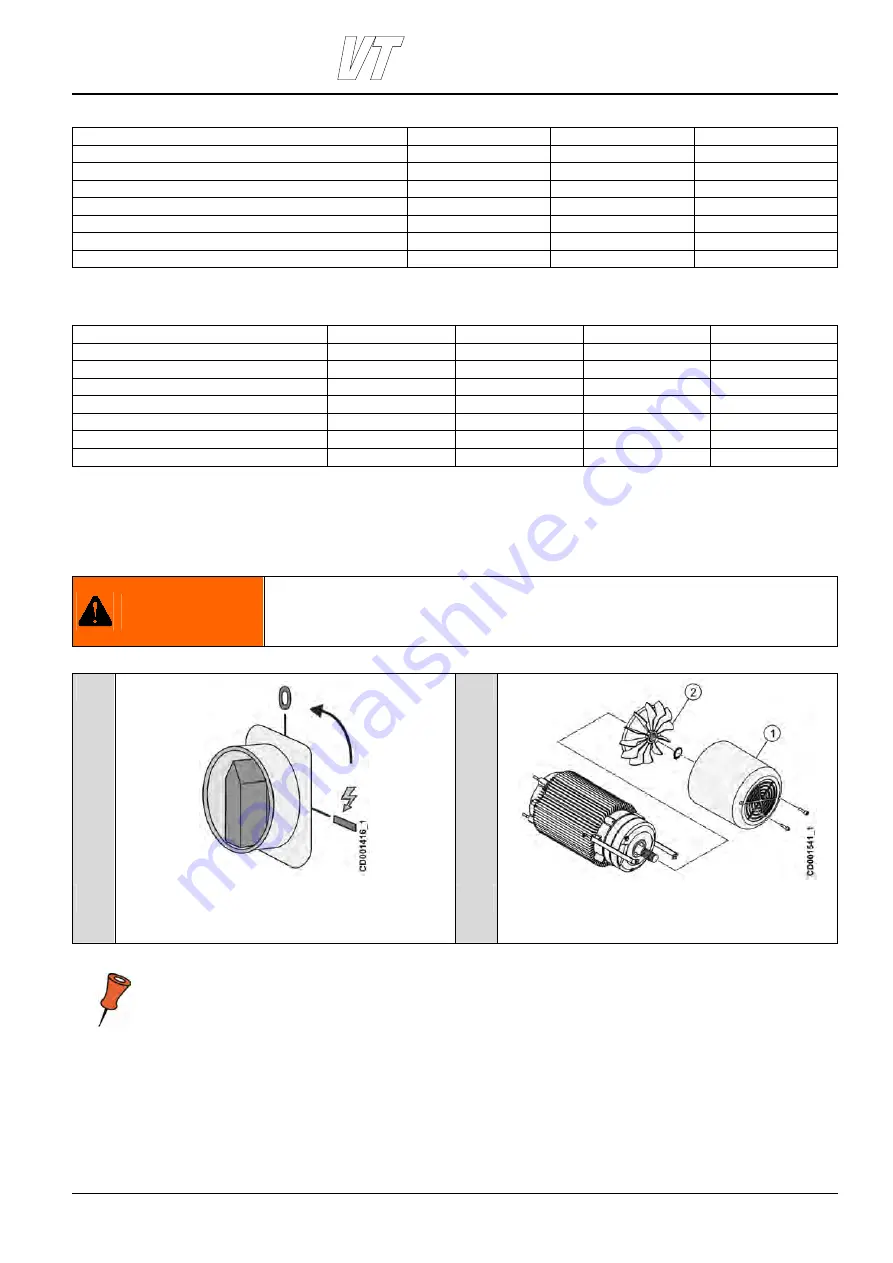

1

2

Lower the hook to the ground. Switch OFF the power supply

to the hoist. Remove the protective cover of the hoisting

machinery. Lock the rope drum with a wooden wedge to

prevent it from rotating.

Remove the fan cover (1) and fan (2).

Note: Place your fingers behind the fan and carefully pull the fan off the shaft.