EUROBLOC

SERVICE MANUAL FOR HOIST

31/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

Component

In

te

rv

a

l

Inspection and maintenance task

Interval is SWP% reduction or calendar months

See further instructions

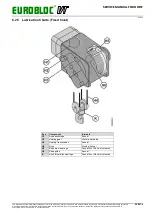

Motor/gear

coupling

*)

Investigate the condition of the coupling between the motor and the gear.

The coupling must be replaced if there is any visible damage or rust

inside the coupling or if the o-rings have any visible damage or signs

of aging.

Lubricate the coupling and motor splines carefully.

*) Interval

Hoist classification

M5/M6

M3/M4

Hoists with CID

SWP% reduction

40%

80%

Calendar period. Years

8

8

Hoists without CID

Calendar period. Years

5

5

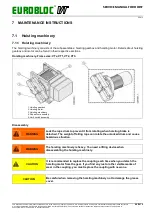

Hoisting gearbox

Maintenance task for hoisting gear

Lubrication

Mechanical component

Component

In

te

rv

a

l

Inspection and maintenance task

Interval is SWP% reduction or calendar months

See further instructions

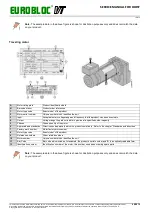

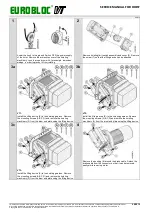

Rope drum

10%

12

Rotation of a rope drum and the condition of bearings:

Check the proper rotation of a drum and the condition of bearings. Drive

with and without load. Pay attention to the running sound of the rope drum

bearings and check that the rope drum does not touch with the machinery

end plates or other parts.

Lubricate the drum bearings on both sides of the drum if not life- time

lubricated.

Rope drum

Maintenance tasks for rope drum

Drum wear inspection

Rope clamps

Lubrication

10%

12

Inspect the condition and cleanliness of rope drum.

Check visually the grooves of the drum. Measure the groove wear if

needed.

Clean and lubricate the drum surface.

10%

12

Axial locking part on certain frame sizes:

Inspect the condition and operation of the axial locking part.

The axial locking part must be replaced when worn 5 mm or more.

Clean and lubricate the locking part groove.

10%

12

Inspect the fixing of the connection rods:

Check visually that the connection rods are straight and the fixing screws

are tight.

10%

12

Check the gear rim.

Check the gear rim for possible unusual noise during operation.

Lubricate the gear rim.

10%

12

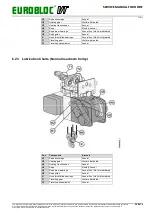

Inspect the condition and correct fastening of rope clamp.

Check that the rope clamp bolts are tight.

Ensure that there are friction turns when the hook is at the lowest position.

Ensure that the rope end protrudes from the last clamp to the specified

length.

Rope guide

10%

12

Inspect the condition of the rope guide.

Test the proper operation of the rope guide.

Inspect the rope guide for loose or missing fittings.

Check the condition of the pressure bearing if present.

Clean the rope guide guiding rod.

Replace the worn parts.

Lubricate the rope guide and the rope guide guiding rod.

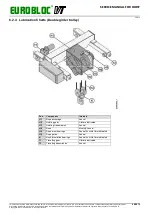

Rope guide

Replacing an old style rope guide with

a heavy-duty rope guide

Lubrication