EUROBLOC

SERVICE MANUAL FOR HOIST

114/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

3

4

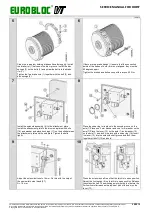

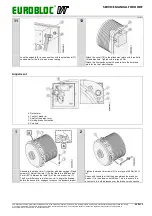

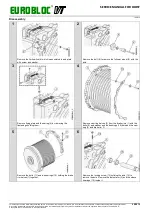

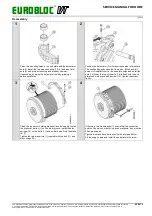

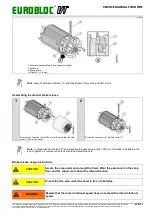

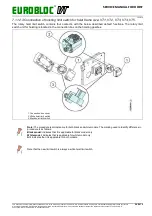

Check the fixing hole for the axle and the detent arm (12)

• No deformation, oval shape or cracks

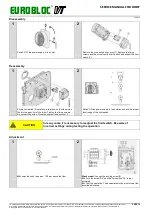

• Change the brake rim (14), screws (15)and disc springs

(16)

• Proceed with all other checks as in normal drum brake

service

• Adjust the brake. Refer to the manufacturer’s hoist test

report.

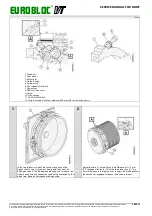

• With every fifth emergency breaking the detent arm and its

shaft has to be changed.

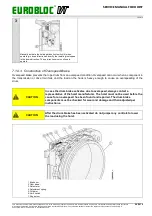

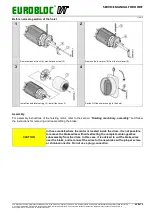

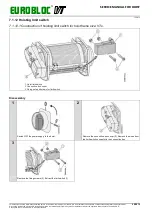

7.1.10 Manual brake release for hoisting motor

CAUTION

The manual brake release is allowed to use only in case of emergency.

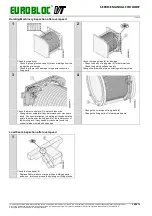

DANGER

FOLLOW THE INSTRUCTIONS FOR USAGE CAREFULLY. POTENTIAL ENERGY

OF LOAD WILL HEAT UP THE BRAKE RAPIDLY. OVERHEATED BRAKE CAN

CAUSE UNCONTROLLED LOWERING, ACCELERATING ROTATION SPEED

AND EXPLOSION OF MACHINERY. UNCONTROLLED LOWERING CAN

RESULT SERIOUS INJURY OR DEATH.

CAUTION

It is recommended to contact a service agency authorized by the manufacturer

if there is a need to use manual brake release. Especially trained personnel are

able to ensure the safe lowering of the load.

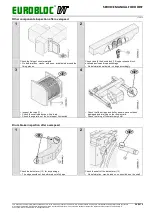

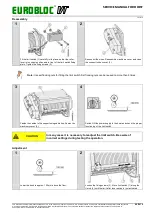

CAUTION

In hoist models that are equipped with a second brake (optional), both brakes

must be manually opened with levers simultaneously. This requires two

persons to carry out the action.

CAUTION

In hoist models that are equipped with two hoisting motors (and thus two main

brakes), both brakes must be manually opened with levers simultaneously.

This requires two persons to carry out the action.