97

107672-01- 7/17

11) Start the boiler using the lighting instructions on page 102. With the boiler powered up, and with no call for heat, the

display should look like Figure 11.2a. Once a call for heat is present, it will look like Figure 11.2b.

12)

The boiler should attempt to fire approximately 30 seconds after a call for heat appears. With the upper front cover

removed from the boiler, this try for ignition will appear as an audible spark (lasting approximately 4 seconds) and an

audible click from the gas valve. Upon initial start-up, the gas train will be filled with air. Even if the gas line has been

completely purged of air, it may take several tries for ignition before a flame is established. If the boiler does not light

after six tries for ignition, it will enter a “soft lockout” and will wait for one hour before attempting another ignition

sequence. This soft lockout can be reset by interrupting power to the boiler for a few seconds. Once a flame has been

established for the first time, subsequent calls for burner operation should result in a flame on the first try.

13)

If there is a problem that appears before the first try for ignition, or if the boiler fails to light after six tries for ignition, the

blinking “HELP” button is highlighted on the Home screen (Figure 11.2c). Touching this “HELP” button will take the

user to the Diagnostics menu where the cause of the problem can usually be found by pressing the flashing button on each

successive screen.

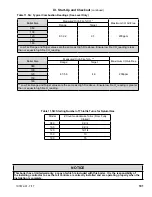

Note: If boiler does not start when first turned on, and problem cannot be remedied following “Help” prompts on the

boiler display, it may be necessary to reset and adjust the throttle screw according to the following instructions:

1.

Fully close throttle

by turning throttle screw clockwise until it fully stops.

2.

Open throttle screw

counter-clockwise the number of full (360 degrees) and partial turns listed in Table 11.5B.

14)

Inspect the flame visible through the window. On high fire the flame should be stable and mostly blue (Figure 11.3). No

yellow tipping should be present; however, intermittent flecks of yellow and orange in the flame are normal.

15) Check the inlet gas pressure. Verify that the inlet gas pressure is between the upper and lower limits shown on the rating

plate with all gas appliances on and off.

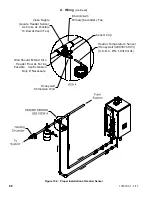

Figure 11.1: Location of Manual Air Vent

XI. Start-Up and Checkout

(continued)

FLAME ROD

ATTACH 1/4" ID CLEAR

TUBING TO HOSE BARB

AND ROUTE TO SAFE PLACE

AWAY FROM CONTROLS

BEFORE OPENING VENT.

MANUAL AIR VENT

Содержание K2WT-080B

Страница 11: ...11 107672 01 7 17 Figure 5 1 Wall Layout Mounting Hole Location V Mounting The Boiler continued...

Страница 79: ...79 107672 01 7 17 Figure 9 6 Piping Method 1 Near Boiler Piping Shaded Boiler Loop IX System Piping continued...

Страница 83: ...83 107672 01 7 17 PAGE LEFT INTENTIONALLY BLANK...

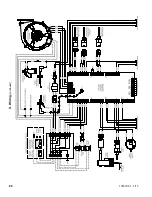

Страница 89: ...89 107672 01 7 17 X Wiring continued Figure 10 5 Internal Ladder Diagram...

Страница 90: ...90 107672 01 7 17 X Wiring continued...

Страница 91: ...91 107672 01 7 17 Figure 10 6 Internal Wiring Connections Diagram X Wiring continued...

Страница 93: ...93 107672 01 7 17 Figure 10 8 TACO SR504 or Equivalent Zone Panel Wiring Connection Diagram X Wiring continued...

Страница 94: ...94 107672 01 7 17 X Wiring continued Figure 10 9 Sage Zone Control Circulator Panel Wiring Connection Diagram...

Страница 102: ...102 107672 01 7 17 Lighting and Operating Instructions XI Start Up and Checkout continued...

Страница 147: ...147 107672 01 7 17 XV Service Parts continued...

Страница 151: ...151 107672 01 7 17 XV Service Parts continued...

Страница 153: ...153 107672 01 7 17 XV Service Parts continued 85 86 91 95...

Страница 162: ...162 107672 01 7 17...

Страница 163: ...163 107672 01 7 17...

Страница 164: ...164 107672 01 7 17...

Страница 165: ...165 107672 01 7 17...

Страница 166: ...166 107672 01 7 17...

Страница 167: ...167 107672 01 7 17...

Страница 168: ...168 107672 01 7 17 U S Boiler Company Inc P O Box 3020 Lancaster PA 17604 1 888 432 8887 www usboiler net...