108

107672-01 - 7/17

XII. Operation

(continued)

Status Screen Display

Description

Priority:

Standby

Status:

Standby

(burner

Off

, circulator(s)

Off

)

Boiler is not firing and there is no call for heat, priority equals standby. The boiler

is ready to respond to a call for heat.

Priority:

Central Heat

Status:

Standby

(burner

Off

, circulator(s)

On

)

Boiler is not firing. There is a Central Heat call for heat and the Supply temperature

is greater than setpoint minus the “Diff Below”.

Priority:

Central Heat

Status:

Prepurge

When supply temperature drops burner demand continues with following Status

shown:

Safe Startup:

Flame circuit is tested.

Drive purge:

The blower is driven to the fan purge speed.

Prepurge:

After the blower reaches the fan purge speed setting the

combustion chamber purge is conducted.

Priority:

Central Heat

Status:

Direct

ignition

After purge time is complete the following Status is shown:

Drive light-off: The blower is driven to light-off rate.

Pre-Ignition Test: After the blower reaches light-off rate a safety relay test is

conducted.

Pre-ignition:

Spark is energized and it is confirmed that no flame is present

Direct Ignition: Spark and Main fuel valve are energized.

Priority:

Central Heat

Status:

Running

(burner

On

, circulator(s)

On

)

After flame is proven the sequence continues with run stabilization and low

fire hold time. Once the field adjustable low fire hold time is completed normal

boiler operation begins, modulation rate depending on temperature and setpoint

selections.

Priority:

Domestic

Hot Water

Status:

Running

If the Central Heat call for heat is active and a Domestic Hot Water (DHW) call for

heat received the DHW demand becomes the “priority” and the modulation rate,

setpoint, “Diff Above” and “Diff Below” are based on DHW settings.

Priority:

Standby

Status:

Post-purge

(burner

Off

, circulator(s)

Off

)

If there is no call for heat the main fuel valve is closed and the blower is driven

to the fan post-purge speed. After the blower reaches the fan post-purge speed

setting the combustion chamber purge is conducted.

Priority:

Standby

Status:

Standby

Delay

Standby delay status is entered when a delay is needed before allowing the burner

control to be available. Select “Help” button from the “Home Screen” to determine

the cause of the Standby Delay.

Priority:

Standby

Status:

Lockout

A lockout status is entered to prevent the boiler from running due to a detected

problem. Select “Help” button from the “Home Screen” to determine the cause of

the Lockout. The last 5 Lockouts are recorded in the Lockout History.

E. Boiler Sequence of Operation

1. Normal Operation

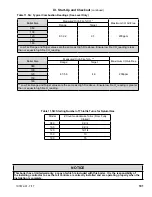

Table 12.3: Boiler Sequence of Operation

Содержание K2WT-080B

Страница 11: ...11 107672 01 7 17 Figure 5 1 Wall Layout Mounting Hole Location V Mounting The Boiler continued...

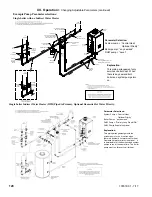

Страница 79: ...79 107672 01 7 17 Figure 9 6 Piping Method 1 Near Boiler Piping Shaded Boiler Loop IX System Piping continued...

Страница 83: ...83 107672 01 7 17 PAGE LEFT INTENTIONALLY BLANK...

Страница 89: ...89 107672 01 7 17 X Wiring continued Figure 10 5 Internal Ladder Diagram...

Страница 90: ...90 107672 01 7 17 X Wiring continued...

Страница 91: ...91 107672 01 7 17 Figure 10 6 Internal Wiring Connections Diagram X Wiring continued...

Страница 93: ...93 107672 01 7 17 Figure 10 8 TACO SR504 or Equivalent Zone Panel Wiring Connection Diagram X Wiring continued...

Страница 94: ...94 107672 01 7 17 X Wiring continued Figure 10 9 Sage Zone Control Circulator Panel Wiring Connection Diagram...

Страница 102: ...102 107672 01 7 17 Lighting and Operating Instructions XI Start Up and Checkout continued...

Страница 147: ...147 107672 01 7 17 XV Service Parts continued...

Страница 151: ...151 107672 01 7 17 XV Service Parts continued...

Страница 153: ...153 107672 01 7 17 XV Service Parts continued 85 86 91 95...

Страница 162: ...162 107672 01 7 17...

Страница 163: ...163 107672 01 7 17...

Страница 164: ...164 107672 01 7 17...

Страница 165: ...165 107672 01 7 17...

Страница 166: ...166 107672 01 7 17...

Страница 167: ...167 107672 01 7 17...

Страница 168: ...168 107672 01 7 17 U S Boiler Company Inc P O Box 3020 Lancaster PA 17604 1 888 432 8887 www usboiler net...