65

107672-01- 7/17

VII. Venting

I. Assembly of Stainless Steel Vent Systems (continued)

d. When flexible stainless steel pipe is used for combustion product venting, it must be installed at vertical or near vertical

orientation. This will insure proper condensate flow back towards the boiler.

e. Follow flexible stainless steel pipe manufacturer specific instructions regarding application/listing, permits, minimum

clearances to combustibles, installation details (proper joint assembly, pipe support and routing, gasket and fitting

installation, optional tooling availability/usage, routing through masonry combination of combustion product venting and

combustion air supply).

f. When there is a conflict between flexible stainless steel pipe manufacturer installation instructions and Boiler Installation,

Operating and Service Instructions, the more restrictive instructions shall govern.

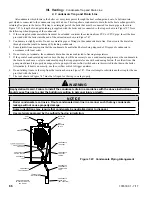

Warning

Asphyxiation Hazard. Flexible stainless steel vent must be installed only in an UNUSED chimney flue. A

chimney flue in considered UNUSED when it is not being used for any appliance venting. If chimney is a

multiple flue type where one of the multiple flue is being used for an appliance venting, the flexible stainless

vent installation is permitted through an adjacent, unused flue providing a local authority having jurisdiction

approves such installation.

Asphyxiation Hazard. Flexible stainless steel pipe must be installed at vertical or near vertical plane when

used for combustion product venting. Failure to do so will result in improper condensate drainage towards

the boiler and possible subsequent vent pipe blockage.

Содержание K2WT-080B

Страница 11: ...11 107672 01 7 17 Figure 5 1 Wall Layout Mounting Hole Location V Mounting The Boiler continued...

Страница 79: ...79 107672 01 7 17 Figure 9 6 Piping Method 1 Near Boiler Piping Shaded Boiler Loop IX System Piping continued...

Страница 83: ...83 107672 01 7 17 PAGE LEFT INTENTIONALLY BLANK...

Страница 89: ...89 107672 01 7 17 X Wiring continued Figure 10 5 Internal Ladder Diagram...

Страница 90: ...90 107672 01 7 17 X Wiring continued...

Страница 91: ...91 107672 01 7 17 Figure 10 6 Internal Wiring Connections Diagram X Wiring continued...

Страница 93: ...93 107672 01 7 17 Figure 10 8 TACO SR504 or Equivalent Zone Panel Wiring Connection Diagram X Wiring continued...

Страница 94: ...94 107672 01 7 17 X Wiring continued Figure 10 9 Sage Zone Control Circulator Panel Wiring Connection Diagram...

Страница 102: ...102 107672 01 7 17 Lighting and Operating Instructions XI Start Up and Checkout continued...

Страница 147: ...147 107672 01 7 17 XV Service Parts continued...

Страница 151: ...151 107672 01 7 17 XV Service Parts continued...

Страница 153: ...153 107672 01 7 17 XV Service Parts continued 85 86 91 95...

Страница 162: ...162 107672 01 7 17...

Страница 163: ...163 107672 01 7 17...

Страница 164: ...164 107672 01 7 17...

Страница 165: ...165 107672 01 7 17...

Страница 166: ...166 107672 01 7 17...

Страница 167: ...167 107672 01 7 17...

Страница 168: ...168 107672 01 7 17 U S Boiler Company Inc P O Box 3020 Lancaster PA 17604 1 888 432 8887 www usboiler net...