- 17 -

10.4 TU32H

Figure 28 on page C shows the location of the

SUPERTIRFOR™ safety pin.

To replace the pin, proceed as follows:

1) Remove the sheared SUPERTIRFOR™ pin using a pin

drift.

2) Clean the pin housings.

3) Line up the hole of the forward operating lever (item 1)

with that of the support yoke (item 2) (figure 28, page C).

4) Fully engage the new replacement SUPERTIRFOR™

pin (located in the clutch handle, item 22, figure 3,

page 7) into the housing by tapping lightly with the

hammer.

Before returning the machine to service, make sure that the

cause of the overload has been eliminated. If necessary, set

up a pulley block system (see figures 10 and 11, page A).

11. SUPERTIRFOR™ WIRE ROPE

(5 STRANDS MINIMUM)

To ensure safe use of the SUPERTIRFOR™ machines,

only SUPERTIRFOR™ wire ropes specially designed for

these machines should be used. The SUPERTIRFOR™

wire ropes have a red strand which is visible when new and

the TRACTEL logo at the location where the

SUPERTIRFOR™ wire rope loop is crimped.

For an installation requiring a very long SUPERTIRFOR™

wire rope (> 80 m), in particular when a pulley block system

is used, contact TRACTEL.

One end of the SUPERTIRFOR™ wire rope is equipped

with a safety hook mounted on a loop formed by the

SUPERTIRFOR™ wire rope, equipped with a lug and

crimped in a metal sleeve (see figure 40, page C). The

other end of the SUPERTIRFOR™ wire rope is welded and

ground (see figure 41, page C).

Safety is ensured by regularly verifying that your

SUPERTIRFOR™ wire rope is in good condition and that

your SUPERTIRFOR™ machine is in good condition.

You must therefore regularly monitor the condition of the

SUPERTIRFOR™ wire rope, clean it and lubricate it using

a rag moistened with oil or grease.

IMPORTANT

: Never use greases or oils containing

molybdenum disulfide or graphite additives.

The SUPERTIRFOR™ wire rope must be visually

inspected before each use for signs of possible damage

(see figure 42, page C).

If any visible deterioration is observed, have the

SUPERTIRFOR™ wire rope examined by a qualified

technician. Any SUPERTIRFOR™ wire rope for which wear

has reduced the nominal diameter by 10% must be

eliminated (measure diameter as indicated in figure 43,

page C).

IMPORTANT

: We recommend, especially for lifting

operations, that you ensure that the length of the

SUPERTIRFOR™ wire rope is greater than the travel

distance to be used. Provide at least one meter of

additional wire rope length to ensure that it goes past the

machine casing, on the anchoring side.

When lifting or lowering loads on very long wire ropes, you

should keep the load from turning to prevent un-stranding

of the SUPERTIRFOR™ wire rope.

Never allow a tensioned SUPERTIRFOR™ wire rope to rub

against an obstacle when lifting or lowering ; only pulleys

should be used. The diameter of the pulley groove must be

equal to at least 16 times the diameter of the cable (check

applicable regulations if necessary).

IMPORTANT

: Do not expose the SUPERTIRFOR™

wire rope to temperatures exceeding 100°C or to

mechanical or chemical agents which could damage the

wire rope.

Storage: see chapter 8.

12 MAINTENANCE OF MACHINES

12.1 SUPERTIRFOR™ MACHINES TU16H and

TU32H

IMPORTANT

: Never use oil or grease containing

molybdenum disulfide or a graphite additive. Servicing the

machine consists in cleaning and oiling the unit, and having

it periodically inspected (at least annually) by an approved

TRACTEL

®

repair agent.

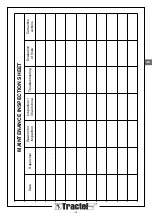

The inspection and maintenance sheet is located at the

end of this manual.

To clean the machine:

1) Disconnect the load from the machine, then disconnect

the machine from the hydraulic power pack.

2) Immerse it entirely in a solvent bath such as petroleum,

gasoline, white-spirit; do not use acetone, or

trichloroethylene, or any of their derivatives.

3) Shake it to remove any mud and other foreign matter.

Turn over the machine so that any dirt which it may

contain will come out through the lever opening. Allow it

to drip and dry.

4) The mechanism must then be generously lubricated by

pouring in oil (type SAE 90).

5) Release the mechanism first. The machine should be

free of any load. Operate the levers to facilitate

penetration of the oil in all the parts of the mechanism.

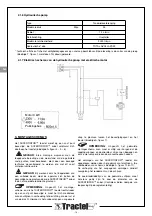

12.2 Hydraulic power pack and hoses

Servicing the hydraulic power pack consists in cleaning it

and having it inspected periodically (at least annually) by a

TRACTEL

®

approved repair agent.

Fill with oil through the tank filler hole.

Check that the valves are clean at the hose ends which

should be equipped with dust covers. Each time you

connect the hoses to the rams, check that the valves are

clean (after each disconnection, be sure to fit the covers on

the valves).

In case of intensive use, you should change the hydraulic

oil every 6 months.

GB

Содержание Supertirfor TU16H

Страница 21: ... 21 FR 16 6 Plaques des caractéristiques du moteur électrique ...

Страница 43: ... 21 16 6 Plates indicating technical data of electric motor GB ...

Страница 65: ... 21 16 6 Plaat met de eigenschappen van de elektrische motor NL ...

Страница 87: ... 21 16 6 Typenschilder des Elektromotors DE ...

Страница 91: ... B 28 22 16b 16a 27 3 1 14 29 2 D B 27 31 C 16 A 29 15 1 28 16b 16a 17 18 19 1 20 23 24 25 21 A B 23 30 24 ...

Страница 95: ......