3-32

Item

8. Release valve

control

(Continued)

Operation explanation and applied data, etc.

1) Contents of control

SV2 is opened when the following conditions are satisfied.

• Compressor status changes from OFF to ON.

• During defrost control

(From when 4-way valve is turned off.)

• Oil recovery controlling is performed in cooling mode.

• SV2 is opened when TK3 sensor detects 2°C or lower

temperature, and closed when TK3 sensor detects 5°C or higher

temperature during compressor-ON time.

• No. of outdoor fan waves is 3 waves or less during cooling

compressor-ON.

(5) SV41, 42 low pressure release control

This control is to prevent low pressure lowering in defrost operation.

This control is individually executed by the master outdoor unit and

each terminal outdoor unit.

This control is executed during defrost operation or activation time of

the heating operation.

1) Contents of control

SV41 and 42 are opener (ON) when PS pressure

≤

0.05 MPa, and

they are closed (OFF) when PS pressure

≥

0.1 MPa.

Remarks

9. Fixed-speed

compressor

high pressure

release

control

• No. 2 compressor

stops with

Pd

≥

P1 = 2.80 MPa,

• No. 1 compressor

stops with

Pd

≥

P1 = 2.90 MPa,

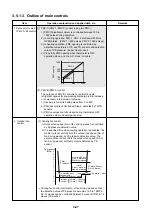

40˚C

TK3

35˚C

25˚C

C zone

B zone

A zone

10. Compressor

winding

heating

control

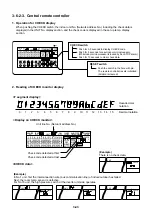

A zone

Continuous

switch-on power

B zone

Intermittent switch-on power

ON : 10 minutes

OFF : 5 minutes

C zone

No

switch-on power

This control is to stop the fixed-speed compressor of each outdoor unit

according to Pd pressure value. This control is individually executed by

the master outdoor unit and each server outdoor unit.

1) Contents of control

• The fixed-speed compressor stops when Pd pressure is over P1.

• Sets the fixed-speed compressor reactivation-proof timer for 10

minutes, and this control finishes.

This control is to prevent stagnation of refrigerant in the compressor case

by turning on electricity to heat windings while the inverter compressor

stops. This control is executed by the master outdoor unit (For inverter

unit) only.

If electricity is not turned on for a specified time before trial operation

when installation work has finished, a fault of the compressor may be

caused. When the power supply has been interrupted for a long time, and

the operation starts from the status that the power supply has been left

as it was, it is desirable to turn on the power before start of operation as

per the trial operation time.

(1) Control conditions

Compressor stops and TD < 35°C.

(2) Contents of control

This control is executed by temperature detected by TK3 sensor as

shown in the following figure.

NOTE :

Sound of turning-on power may be heard during heat winding operation,

but it is not an error/fault.

Содержание MMC-P0151H

Страница 198: ...3 195 108 109 101 102 133 106 131 105 135 128 104 103 111 110 123 116 132 119 120 121 MMY MP06018 ...

Страница 206: ...3 203 108 109 101 102 133 106 131 105 135 128 104 103 111 110 123 116 132 119 120 121 MMY MP0601H8 ...

Страница 214: ...3 211 108 109 101 102 133 106 131 105 135 128 104 103 111 110 123 116 132 119 120 121 MMY MP0601H7 ...

Страница 216: ...TOSHIBA CARRIER CORPORATION 336 TADEHARA FUJI SHI SHIZUOKA KEN 416 8521 JAPAN ...