3-142

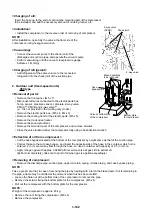

<Charging of oil>

Insert the hose up to the end of suction pipe mounting part of the compressor

to be installed, and add the necessary amount of oil using funnel, etc.

<Installation>

• Install the compressor in the reverse order of removing of compressor.

NOTE :

After installation, open fully the valve at bottom side of the

compressor, using hexagonal wrench.

<Vacuuming>

• Connect the vacuum pump to the check joint of the

discharge and suction pipes, and operate the vacuum pump.

• Perform vacuuming until the vacuum low-pressure gauge

indicates 1 (mmHg).

<Charging of refrigerant>

• Add refrigerant of the same volume to the recovered

refrigerant into the check joint of the suction pipe.

2. Outdoor unit (fixed-speed units)

060 type

<Removal of parts>

• Remove the front panel. (M5 x 7)

• Disconnect all wires connected to the electric parts box.

Temp. sensor, pressure sensor, complete, 2-way valve,

PMV A

*

, PMV B and 4-way valve

*

(

*

: It is not provided in the cooling only model.)

• Remove the electric parts box. (M5 x 4, M4 x 3)

• Remove the cooling duct for the electric parts. (M5 x 5)

• Remove the crank case heater.

• Remove the sound-proof mat.

• Remove the terminal cover of the compressor, and remove all wires.

• Close the valve located under the compressor fully using a hexadecimal wrench.

<Extraction of oil from compressor>

• Cut the case bypass located at the bottom of the compressor by height same as that of the suction pipe.

• Connect hose to the cut case bypass, and insert the opposite side of the hose in the container which oil is

entered. 2

l

or more oil may flow through the hose, so use a container with capacity of 2.5

l

or more.

• Apply nitrogen gas with approx. 0.02MPa from service valve at gas side to extract oil.

(Extract oil completely.) (Be sure to spurt of oil when gas is applied exceedingly.)

<Removing of compressor>

• Remove the discharge pipe, suction pipe, upper oil return piping, oil tank piping, and case bypass piping.

NOTE :

Take a great care that, in case of removing the pipe by heating with a torch the brazed part, if oil is remaining in

the pipe, a flame may be emitted at the moment when flux has been melted.

• Loosen the flare nut at the bottom side of the compressor to remove the pipe.

• Remove the screws fixing the bottom plate for the compressor. (M5 x 6)

• Pull out the compressor with the bottom plate for the compressor.

NOTE :

Weight of the compressor is approx. 45 kg.

• Remove the nuts fixing the compressor. (M8 x 4)

• Remove the compressor.

Bottom plate

for compressor

Brazed positions

to be removed

Case

bypass pipe

Valve at bottom side

of the compressor

4-way valve

Check joint

2-way valve

(SV3B)

Содержание MMC-P0151H

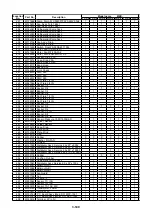

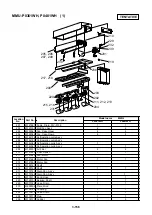

Страница 198: ...3 195 108 109 101 102 133 106 131 105 135 128 104 103 111 110 123 116 132 119 120 121 MMY MP06018 ...

Страница 206: ...3 203 108 109 101 102 133 106 131 105 135 128 104 103 111 110 123 116 132 119 120 121 MMY MP0601H8 ...

Страница 214: ...3 211 108 109 101 102 133 106 131 105 135 128 104 103 111 110 123 116 132 119 120 121 MMY MP0601H7 ...

Страница 216: ...TOSHIBA CARRIER CORPORATION 336 TADEHARA FUJI SHI SHIZUOKA KEN 416 8521 JAPAN ...