3-135

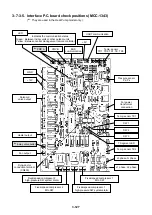

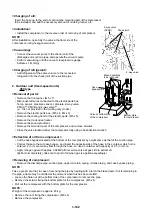

SV3C valve

Check joint

TK1

sensor

Strainer

Strainer

Strainer

Oil

separator

Capillary

Accumulator

Capillary

TK2

sensor

Compressor

Check

valve

Check

valve

Oil

removal

valve

Check

valve

SV3B

valve

Oil

tank

SV3A

valve

Balancing pipe valve

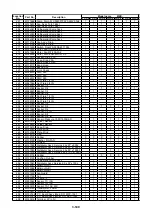

Check code

d7

d8

d9

db

dC

Check code name

Low oil level detection protection

TK1 temp. detection circuit alarm

TK2 temp. detection circuit alarm

Oil level detection circuit blockage detection

Oil level detection circuit leakage detection

Judgment

Oil level shortage status has been detected continuously for approx. 2 hours

while oil equalizing control was continuously implemented.

Temp. change at the oil tank primary side was not detected while oil level

detection control was implemented.

Temp. change at the oil tank secondary side was not detected while oil level

detection control was implemented.

Temp. change at both the oil tank primary side and secondary side was not

detected while oil level detection control was implemented.

The status that TK1 temp. is high (50°C or more) was continuously detected

for a long time.

Operation starts.

→

During operation.

→

Oil level detection control starts.

→

During oil level detection counting.

→

Oil level judgment result.

7 segment display

[OL] [– –]

Counted down every 10 seconds from [OL] [1F]

[OL] [FF]

Counted up every 1 second from [OL] [01]

[OL] [A0] [A1] [A2] [A3] [A4]

Judgment

[A0]

[A1]

[A2]

[A3]

[A4]

Judgment

Oil amount in the compressor is adequate. Check that the operation continues and there is no problem.

If [dC] occurred, execute check even if oil level was judged as adequate.

Oil level was judged as shortage. If this judgment continues, the system stops in protection.

When [d7], [dC] occurred, check according to the check items.

TK1 temp. detection was judged as an error. If this judgment continues, the system stops in protection.

When [d8] occurred, check according to the check items.

Oil level detection circuit (SV3C valve) was judged as blockage. If this judgment continues, the system stops in protection.

When [db] occurred, check according to the check items.

TK2 temp. detection was judged as an error. If this judgment continues, the system stops in protection.

When [d9] occurred, check according to the check items.

3-9. FORCED FUNCTION OF OIL LEVEL DETECTION

(OUTDOOR UNIT)

The oil level detection control can be forcibly implemented by a switch on the interface P.C. board of the outdoor

unit. When an error in the oil tank circuit occurs and there is no cause such as sensor error, connection error, out

of place, valve close operation error, etc., check as follows.

<Oil tank circuit system error>

<Operation procedure>

1) Start the trial operation after alarm was cleared.

2) Set SW01/SW02/SW03 on the interface P.C. board of the outdoor unit to 1/16/1, which oil level is tobe

detected.

3) Push the push-switch SW04 for 2

seconds.

4) Check the 7 segment display on

the P.C. board.

<Oil level judgment result>

<Peripheral circuits of oil tank>

Содержание MMC-P0151H

Страница 198: ...3 195 108 109 101 102 133 106 131 105 135 128 104 103 111 110 123 116 132 119 120 121 MMY MP06018 ...

Страница 206: ...3 203 108 109 101 102 133 106 131 105 135 128 104 103 111 110 123 116 132 119 120 121 MMY MP0601H8 ...

Страница 214: ...3 211 108 109 101 102 133 106 131 105 135 128 104 103 111 110 123 116 132 119 120 121 MMY MP0601H7 ...

Страница 216: ...TOSHIBA CARRIER CORPORATION 336 TADEHARA FUJI SHI SHIZUOKA KEN 416 8521 JAPAN ...