51

LCD Display

Alarm Message

Recommended

Action

Explanation

Remote Input Fail

Check Wiring and

Remote System

Remote Control Input Fail

The Remote Control Input is configured and is not connected or is above or be-

low a valid range. When the remote control input fails, the following control mode

changes are taken automatically:

Selected Modes Resulting Control Mode

Remote Mod Outlet Sensor and Local Setpoint

Remote Mod & Remote Sensor Remote Sensor and Local Setpoint

Remote SP Outlet Sensor and Local Setpoint

Remote SP & Remote Sensor Remote Sensor and Local Setpoint

Comm Failure

Confirm each boiler has

a unique address

Check Wiring and

Remote System

Communication Failure

The Modbus or Peer-To-Peer network has failed. When the Modbus network fails

the following control mode changes are taken automatically:

Selected Modes Resulting Control Mode

Modbus Mod

Outlet Sensor and Local Setpoint

Modbus Mod & Remote Sensor

Remote Sensor and Local Setpoint

Modbus SP

Outlet Sensor and Local Setpoint

Modbus SP & Remote Sensor

Remote Sensor and Local Setpoint

After a Modus communication failure, the ‘Comm Failure’ alarm is not cleared

until communication is restored and successfully writes to both the Remote On

/ Off Modbus Command (00004) and Remote Firing Rate or Remote Setpoint

(40006) points have been completed, power is cycled or the protocol parameter is

changed to Peer-To-Peer and then back to Modbus.

When a Peer-To-Peer network has failed the boilers begin operation as stand

alone boilers using the selected parameters.

After a Peer-To-Peer communication failure the ‘Comm Failure’ alarm is not

cleared until communication is restored and the boiler rejoins a network with at

least one other boiler, power is cycled or the protocol parameter is changed to

Modbus and then back to Peer-To-Peer.

Low Inlet Temp

Check return water

temperature. Consider

system or operational

changes to avoid low

temperature events

Check wiring and

sensor

Low Boiler Inlet Temperature

If the boiler inlet temperature is below the Low boiler inlet temperature setpoint,

the “Low Inlet Temp” Message is displayed and the boiler inlet temperature

history is stored.

Memory Failure

Call Factory Reset

all memories in

System menu:

Clr BIT History

Clr Alarm Hist

Clr Run Time Cnt

Clr Cycle Cnt

Factory Defaults

(Factory Level

Password is required)

Memory Failure

New software has been installed in the Thermal Solutions Boiler Control (TSBC)

or a power interruption has caused a memory failure. The Call For Heat will be

prevented until the condition is cleared.

TROUBLESHOOTING GUIDE (CONTINUED)

Содержание EVCA SERIES

Страница 13: ...13 Figure 3 Typical Sidewall Pressurized Venting Optional Figure 2 Typical Sidewall Pressurized Venting ...

Страница 14: ...14 Figure 4 Typical Vertical Pressurized Venting ...

Страница 16: ...16 Figure 6 Vertical Air Intake Piping Figure 5 Horizontal Air Intake Piping ...

Страница 19: ...19 Figure 8 Schematic Boiler Piping ...

Страница 25: ...25 Figure 9a 208 230 480V 1PH 3PH 60HZ Supply Power Wiring Schematic ...

Страница 26: ...26 Figure 9b 120V 1PH 60HZ Supply Power Wiring Schematic ...

Страница 27: ...27 Figure 9c Control Wiring Schematic EVCA 750 2000 ...

Страница 29: ...29 Figure 9e Control Wiring Schematic EVCA 3000 ...

Страница 32: ...32 Figure 10 Modular System Horizontal Air Intake Piping ...

Страница 33: ...33 Figure 11 Modular System Vertical Air Intake Piping ...

Страница 34: ...34 Figure 12 Modular System Typical One Pipe Water Piping ...

Страница 35: ...35 Figure 13 Modular System Typical Primary Secondary Water Piping ...

Страница 36: ...36 Figure 14 Modular System Typical Primary Secondary without System Pump ...

Страница 37: ...37 Figure 15 Modular System Typical Reverse Return Water Piping ...

Страница 38: ...38 Figure 16 Modular System Reverse Return with System Pump Only ...

Страница 39: ...39 Figure 17 Modular System Typical Primary Secondary with Reverse Return ...

Страница 55: ...55 Figure 18 Cleaning Secondary Heat Exchanger 1 2 ...

Страница 56: ...56 This page intentionally left blank ...

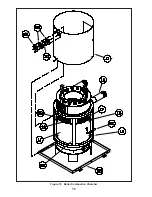

Страница 58: ...58 Figure 19 Boiler Combustion Chamber ...

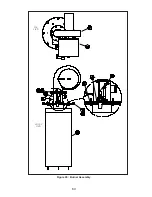

Страница 60: ...60 Figure 20 Burner Assembly FRONT VIEW TOP VIEW ...

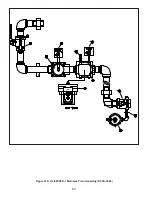

Страница 62: ...62 Figure 21a UL FM CSD 1 Main Gas Train Assembly EVCA 750 2000 ...

Страница 64: ...64 Figure 21b UL FM CSD 1 Main Gas Train Assembly EVCA 3000 ...

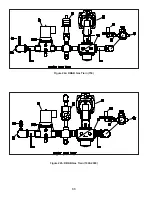

Страница 66: ...66 Figure 22a DB B Gas Train 750 Figure 22b DB B Gas Train 1000 2000 ...

Страница 68: ...68 Figure 22c DB B w POC Gas Train 750 Figure 22d DB B w POC Gas Train 1000 2000 ...

Страница 70: ...70 Figure 22e DB B Gas Train EVCA 3000 Figure 22f DB B w POC Gas Train EVCA 3000 ...

Страница 72: ...72 Figure 23 Jacket ...

Страница 74: ...74 Figure 24 EVCA 750 1000 and 1500 Secondary Heat Exchanger and Housing ...

Страница 78: ...78 Figure 25b EVCA 3000 Secondary Heat Exchanger and Housing ...

Страница 80: ...80 Figure 26 Control Panel Assembly ...

Страница 82: ...82 Figure 27 Bishop Pilot Assembly ...

Страница 97: ...97 NOTES ...

Страница 98: ...98 NOTES ...

Страница 99: ...99 NOTES ...